Thermography for Insulation Checks

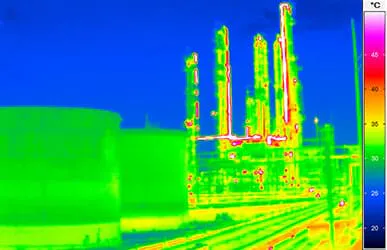

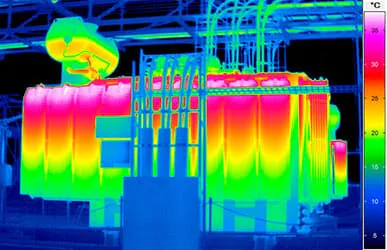

All kind of hot industrial processes need to be contained well to allow the process itself to go on and at the same time to protect neighbouring installations and employees working there. But furnace insulations have also a second very important purpose – energy saving. Especially in times of rising energy costs and environmental protection demands the good shape of furnace insulations becomes increasingly valuable. Thermography helps to detect weak points and provides first indications for necessary repairs.

The world market leader Morgan Thermal Ceramics has been operating in the furnace insulation business for more than 30 years. Being present in nearly all parts of the world for such a long time a vast experience has been gained. Its customers can make use of this experience by expert software predicting the best time for repairs or total replacement of the insulation depending upon a variety of parameters. This is a big step ahead from traditional guts feeling when planning and repairing refractory lining. Still each customer process is different and existing prediction cannot take into account all parameters.

InfraTec Solution

Morgan Thermal Ceramics

www.morganthermal-ceramics.com

Infrared camera

VarioCAM® series

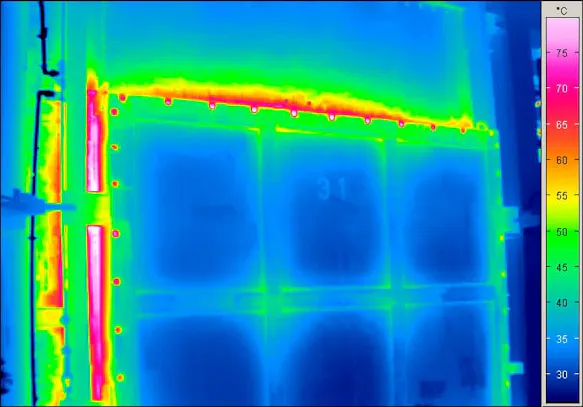

In this situation Steve Chernak and his team thought about thermography. This technology has been around for a while also being used in furnace insulation monitoring. Temperatures can be contactless measured enabling quick and precise measurements when and where needed. Employees will not have to go close to the equipment any longer and can measure from save and convenient distances.

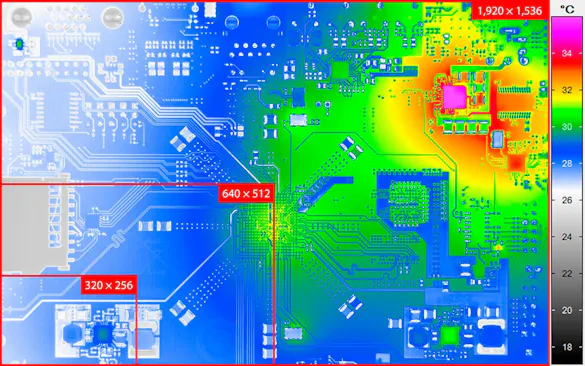

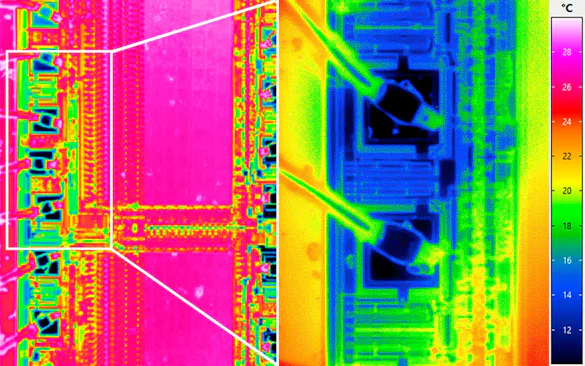

The idea of the team was to compare the suggestions the software models proposed with the findings by using high-quality thermal cameras. Due to the high geometrical resolution of (640 x 480) pixels of the VarioCAM® series infrared camera Steve Chernak gets a large field of view and still can resolve small details. That is making his work very efficient not having to take many images and stitching them together. The other even more important advantage of his camera is the excellent thermal resolution. Thus already minor problems of the insulation materials can be spotted and com-pared with the results of the theoretical software model.

Steve Chernack is sure that combining the recommendations of Morgan Thermal Ceramics´ software and actual findings using an infrared camera can greatly support plant engineers in taking the right and on-time decision between a fast hot-spot repair and a complete installation of new furnace lining.