Temperature Measurement with Thermography

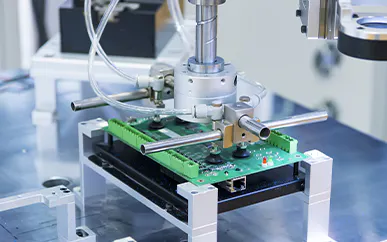

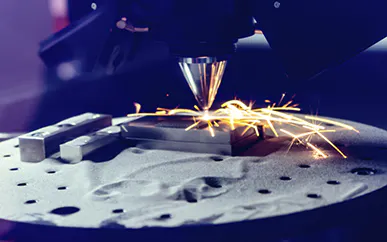

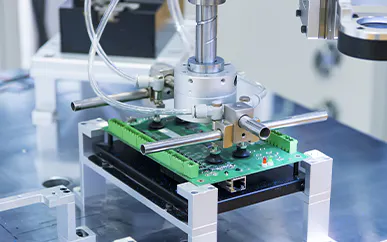

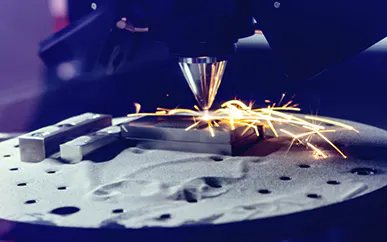

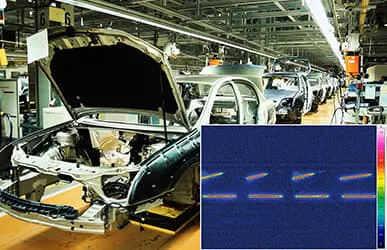

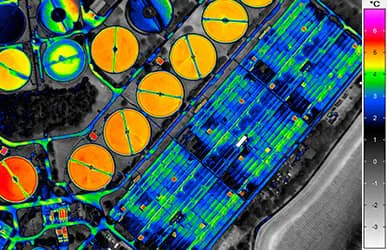

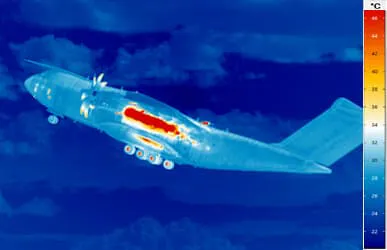

Temperature is a decisive factor in many processes. Be it in the electronics industry, in additive manufacturing or in automotive engineering. One method of determining and monitoring temperature without contact is thermography. It can be used to make defects visible without destroying the test object during testing. This makes it a popular method, especially in the field of non-destructive testing.

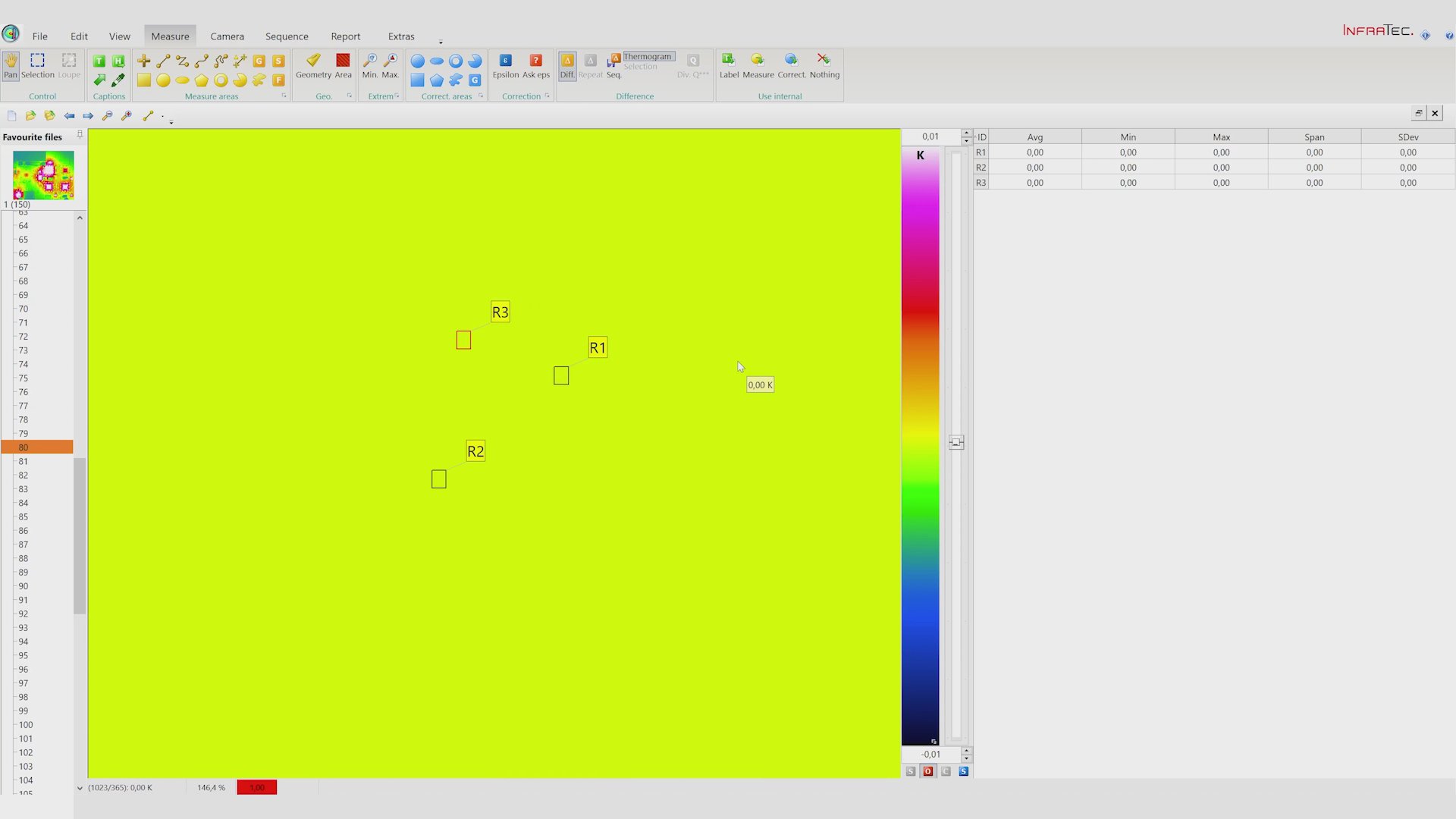

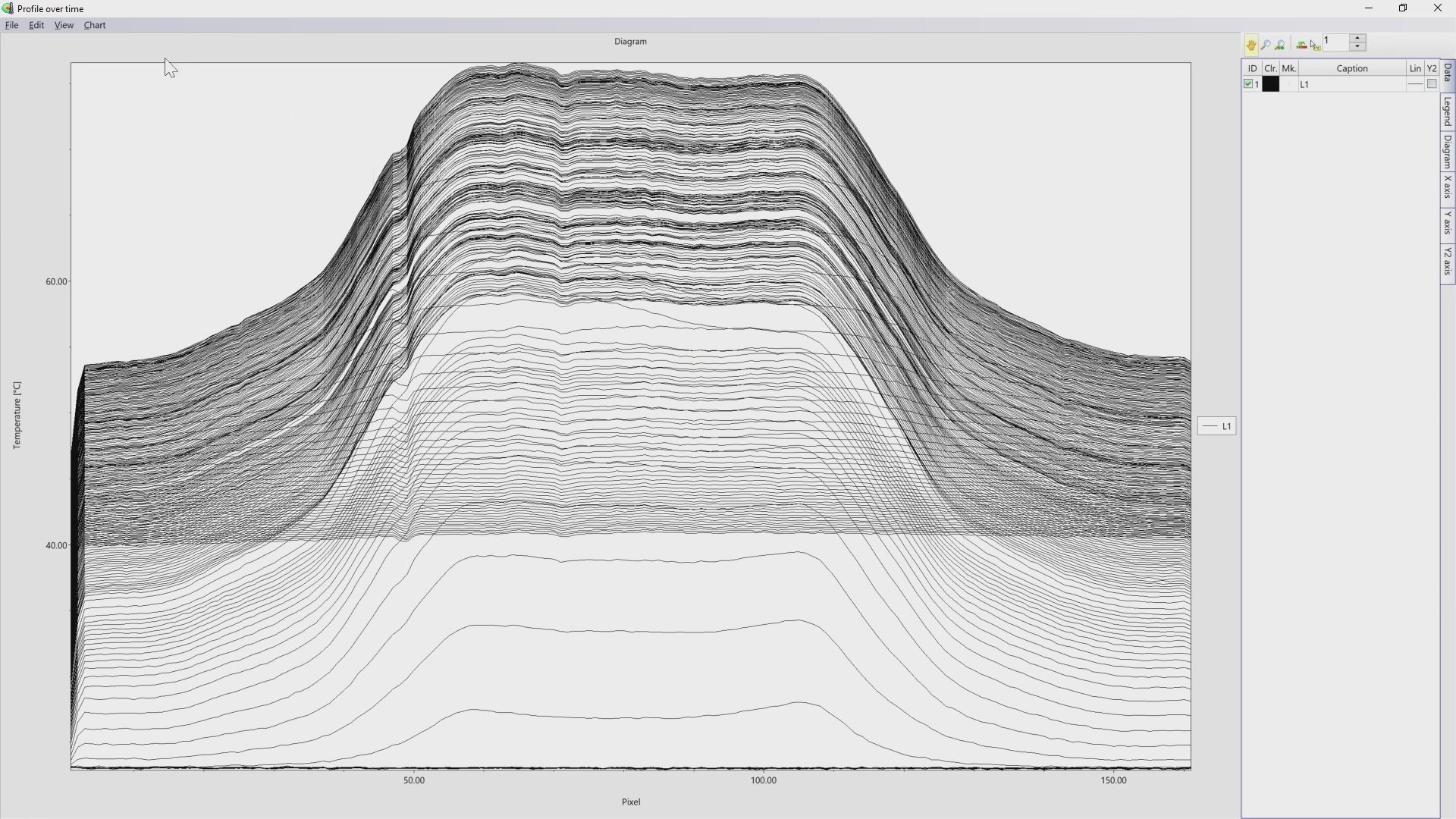

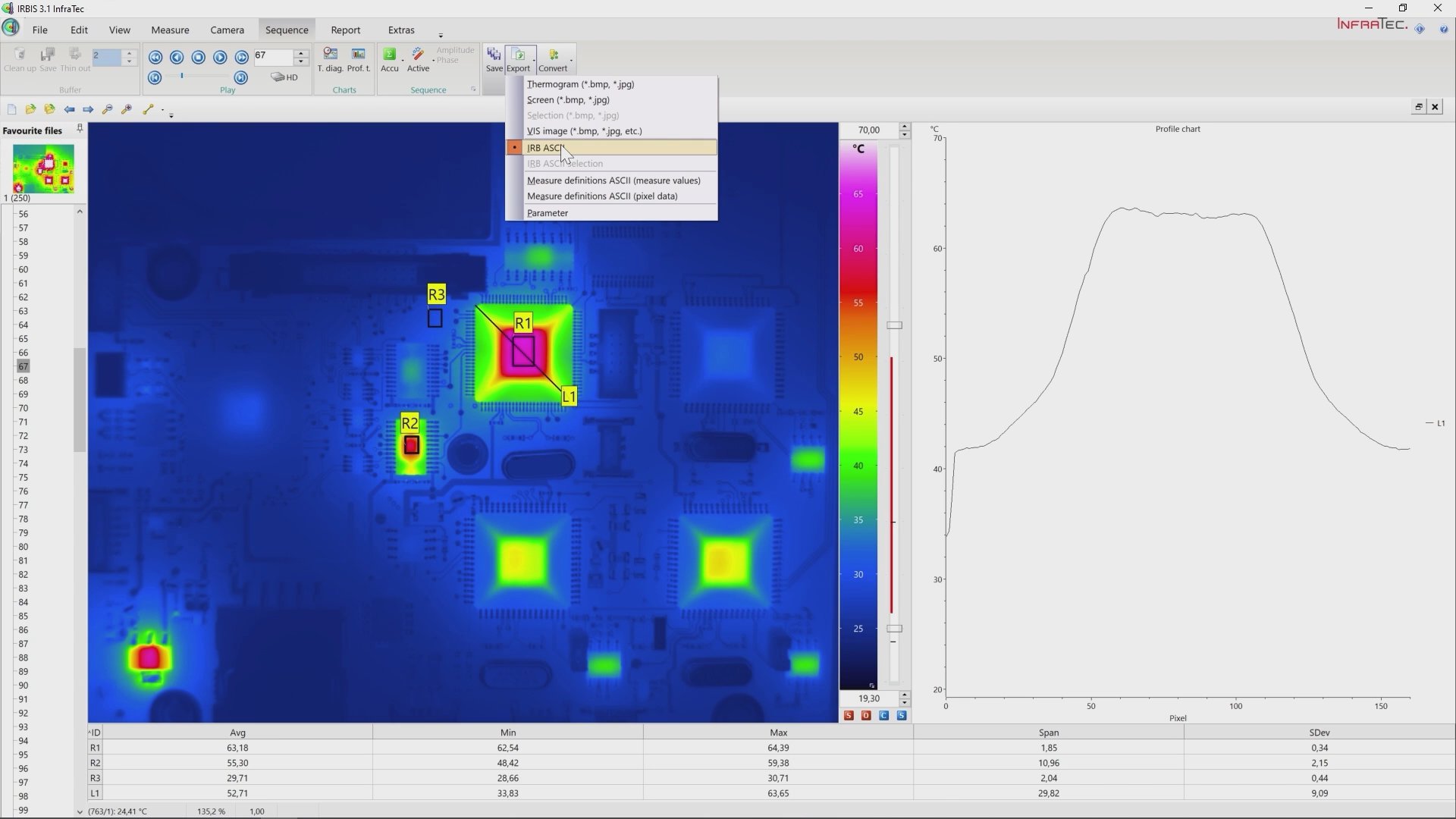

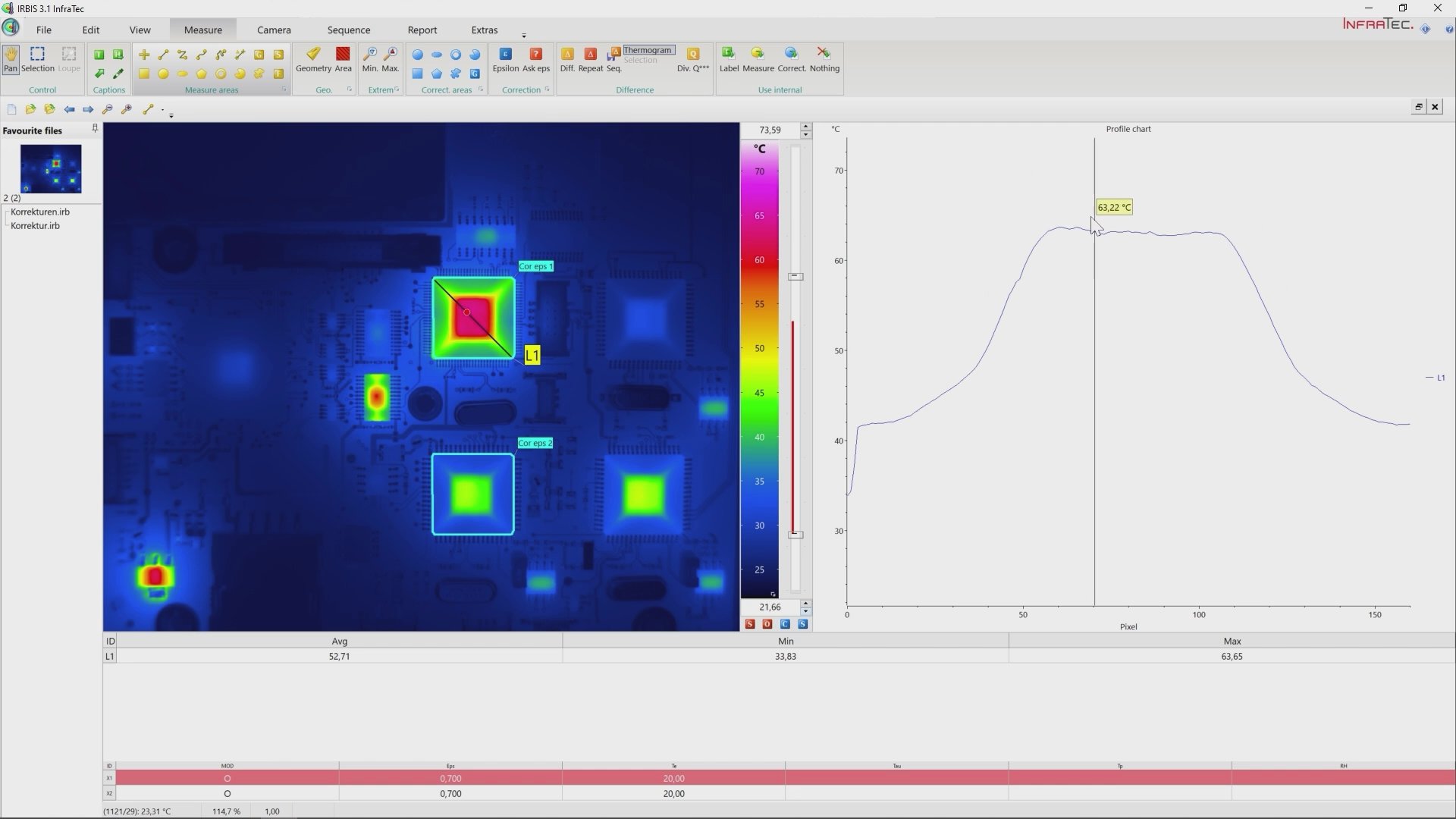

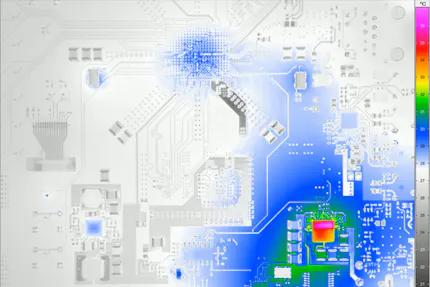

Contact-free measurements of temperature spreads on object surfaces or of processes provide information about the progression of the process or the state of the object. Since thermography is an image-generating process, deviations from the standard, for example, can be detected immediately. This is essential, as even the smallest discrepancies can have a significant impact on functionality and quality.

The principle of infrared thermography is based on the physical phenomenon that any body of a temperature above absolute zero (-273.15 °C) emits electromagnetic radiation. There is clear correlation between the surface of a body and the intensity and spectral composition of its emitted radiation. By determining its radiation intensity, the temperature of an object can thereby be determined in a non-contact way. This is based on a number of physical parameters.

The precondition for a reliable temperature measurement is the use of the right infrared camera. As a specialist for thermography, InfraTec offers a complete range of different thermal imaging cameras for professional, universal use.

Thermography in Use

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.