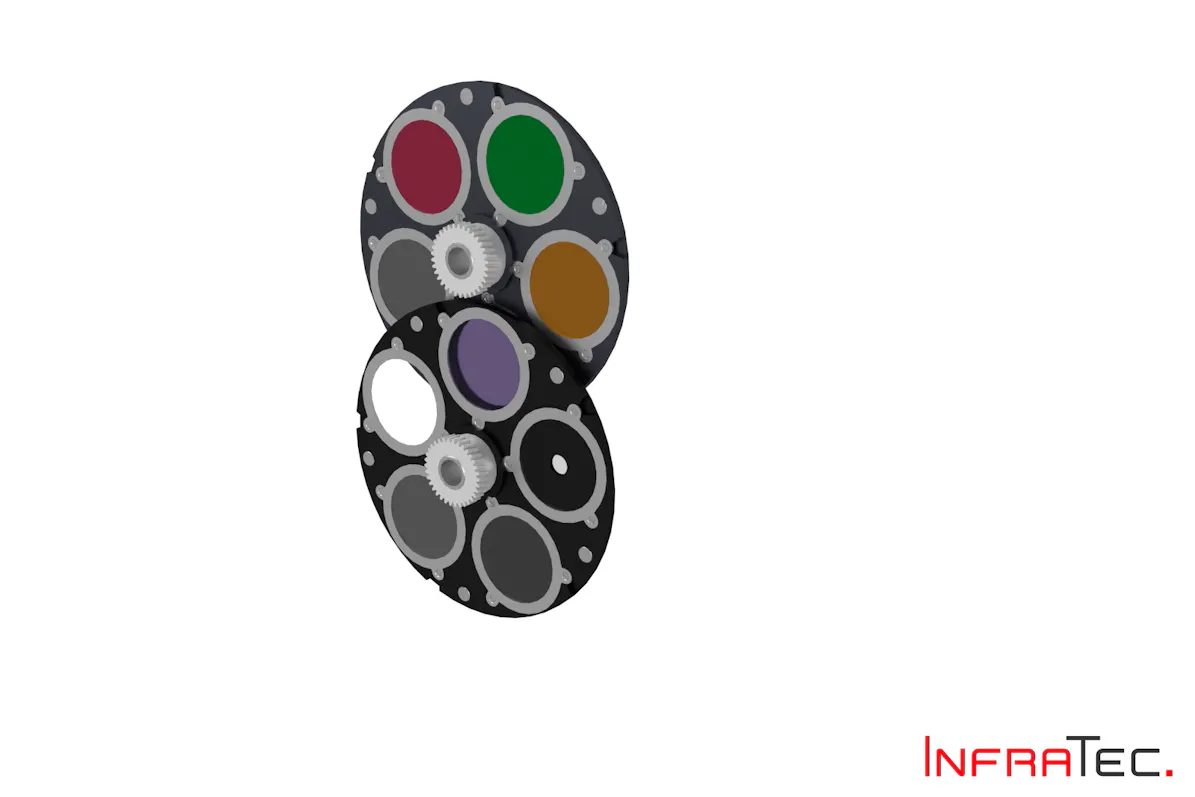

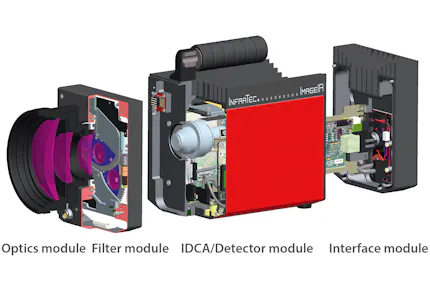

Rotating Filter and Aperture Wheel of the ImageIR® Camera Series

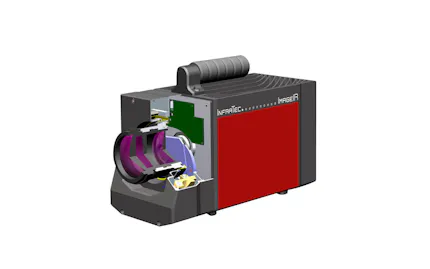

The simultaneous operation of a filter and an aperture wheel, each with up to seven freely assignable positions, significantly expands the capabilities of ImageIR® cameras. This configuration, offered exclusively by InfraTec, enables the universal use of thermography cameras for both high-temperature measurement tasks and applications in spectral thermal imaging.

Adaptation of the Camera to the Spectral Characteristics of the Object

The system design of the ImageIR® thermographic camera enables the integration of up to two independently controllable filter and aperture wheels. The two motorised wheels, which can be individually equipped by InfraTec, allow for up to 35 filter /aperture combinations.

The desired combination is selected entirely via remote control. The freely rotatable and independent wheels are easily moved into the desired position using the corresponding menu in the IRBIS® online camera software – the user just selects the calibration range he wants to work with.

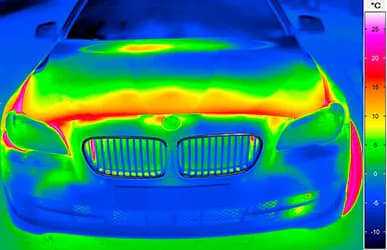

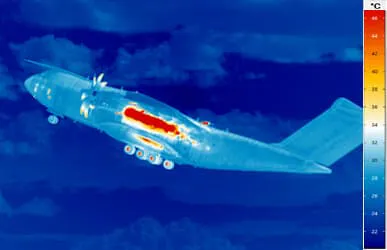

The combination of different filters and apertures via the wheel positions is a prerequisite for the universal use of the camera for measuring tasks in the spectral thermography sector. Spectral filters can be used to adapt the sensitivity range of the camera to the specific requirements of demanding measurement tasks, such as:

Optimised measurement of the surface temperature of shiny metals, glass, plastics, and other materials

Measurement of objects behind glass, gases, or flames

Detection of flames and gases

At very high temperatures – i.e. with intense IR radiation – the detector can quickly become saturated, making meaningful measurement impossible. Apertures can be used to reduce the radiation the detector is exposed to, allowing measurements to be taken even at high temperatures.

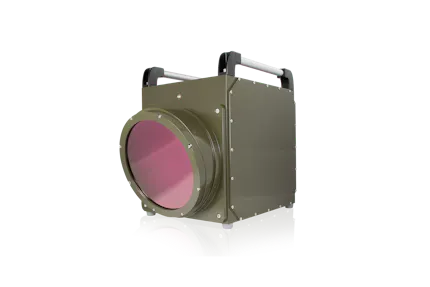

Rotating aperture wheel and filter wheel for infrared camera

Rotating Filter and Aperture Wheel of the ImageIR®

The effects of interference are reliably prevented by apertures or grey filters, which are used for signal monitoring and arranged near to the detector, or by their combination with spectral filters. Furthermore, wide temperature measuring ranges can be achieved with or without spectral filter equipment. Furthermore, wide temperature measuring ranges can be achieved with or without spectral filter equipment.

The use of aperture or grey filters enables temperature measuring ranges up to 3,000 °C. By positioning these filters close to the detector to attenuate the signal – or in combination with spectral filters – interference effects are reliably avoided. In addition, wide temperature measurement ranges can be achieved both with and without spectral filter configurations.

Further possibilities for spectral thermographic measurements arise from narrow bandpass filters (NBP) or the combination of two spectral filters (short-pass and long-pass). This allows, for example, the use of specific absorption bands of objects such as thin films and gases, and the detection of their surface or volume radiation.

An additional option for ImageIR® cameras is the installation of a rotating filter wheel with up to 5,400 revolutions per minute. This enables the implementation of a real-time MicroScan unit to quadruple the number of pixels and thereby to increase the spatial resolution accordingly.

Furthermore, such a fast-rotating filter wheel can be equipped with filters for signal attenuation. This enables the measurement of extremely large temperature gradients by means of the so-called HDR technology (High Dynamic Range). Combining this fast filter wheel with a second aperture or filter wheel allows additional spectral filters to be implemented. Custom filters are optimised and individually tailored to the measurement task.

Rear filter / aperture wheel:

0 = open

1-3 = spectral filter

4 = grey filter

Front filter-/ aperture wheel:

0 = open

1-2 = grey filter

3 = aperture diaphragm

4 = spectral filter

The advantages of filter and aperture wheels at a glance

Extension of the temperature measuring range up to the physically achievable limits: (-40 … 3,000) °C

Use of spectral filters for special applications

Combination of spectral and attenuating filters via two independently controllable wheels, enabling extended spectral measuring ranges

Fully motorised remote control via the IRBIS® 3 camera software, enabling contactless filter control even from greater distances

Option for user-side replacement of the entire filter to expand the camera’s range of applications

Application Examples

Customisable filter and aperture wheels for adaptation to a wide range of measurement tasks

Optimised measurement of glass surfaces or objects behind glass

Detection of flames and gases, as well as measurement of objects behind flames and gases

Use of sun-reflex filters to suppress interference radiation

Real-time measuring range expansion through HDR functionality for measuring highly dynamic thermal objects

High-temperature measurements in welding and laser technology

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.