High-speed Mode

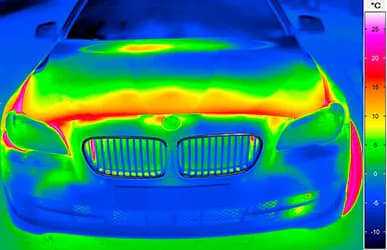

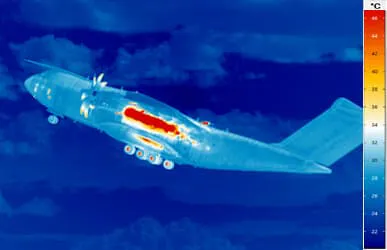

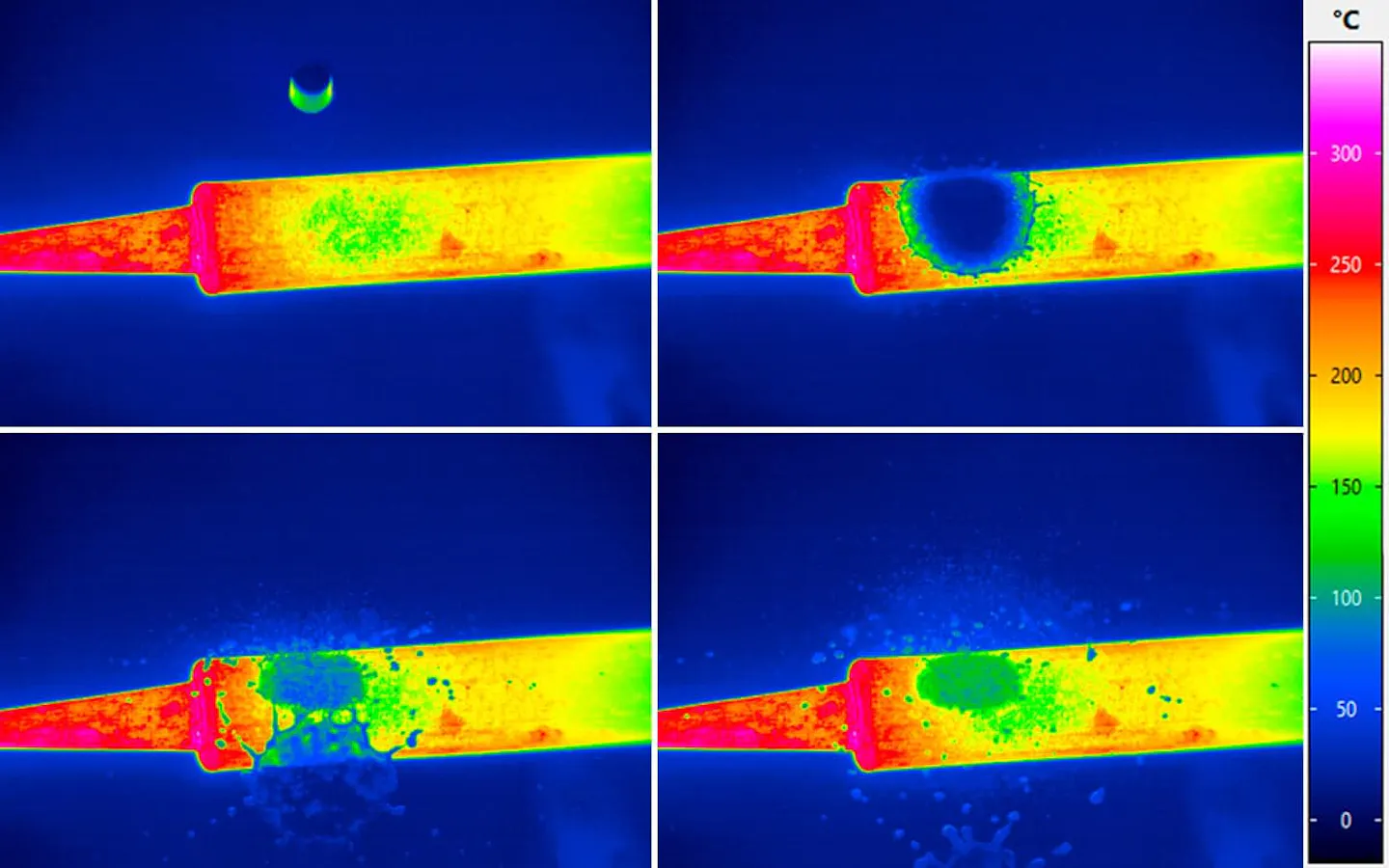

Several models of the high-end camera series ImageIR® from InfraTec offer users the option to choose between two speed modes for the same camera. In standard mode, the familiar frame rates for full frame, half frame and sub-frame are available with full spatial resolution. In high-speed mode, images can be taken with the identical FOV – while the frame rate, i.e. the speed of image processing and image storage, increases to more than three times the previous value.

High-speed Mode for Infrared Camera Series ImageIR®

New High-speed Mode for Thermographic Camera Series ImageIR®

Advantages of Binning

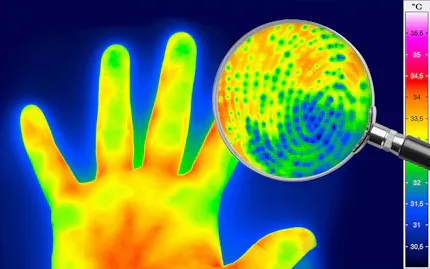

Binning means the hardware combination of pixels of an (IR-)FPA

Resulting in an effective larger new pixel

Larger pixel: better SNR → low NETD

Less amount of pixels: higher frame rate

Same FOV in standard mode (high amount of pixels) and high-speed mode (high speed, low NETD)

Switching between both modes just with a click

Decrease Number of Pixels, Keep the FOV

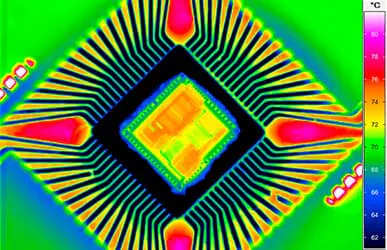

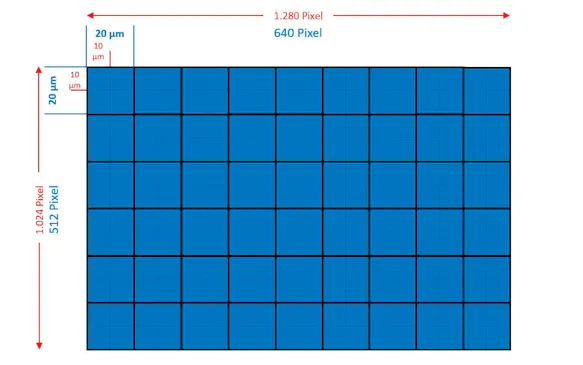

The principle behind this new option is called binning. In the course of this, four pixels of adjacent lines and columns are combined into one pixel in each case. Consequently, the number of pixels of the resulting thermal image decreases. However, the FOV remains constant, so that the scene section captured with the camera does not change. The object distance selected and the lens used can be retained for each respective task.

Of course, the frame rate can also be increased with a conventional infrared camera, for example by changing from full to half frame. However, the FOV changes in this case. The corresponding compensation requires a re-adjustment of the object distance and a correction in relation to the lenses used.

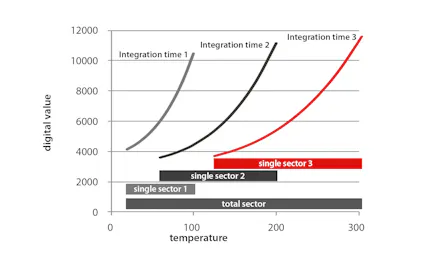

High-speed Mode also Increases the Thermal Resolution

Combining the pixels during binning also results in a higher thermal sensitivity for each virtual pixel. The reason for this is the fact that each readout event of the individual pixels generates associated noise in the signal. A lower number of pixels with a constant detector size automatically implies a reduced readout noise. So together with the larger effective pixel area, the signal-to-noise ratio also improves in high-speed mode of the ImageIR® cameras – by almost a factor of 2. This increase in thermal resolution ensures that even smaller temperature differences can be detected reliably.

Switch Over Once, Benefit Twice

Switching between both speed modes is done conveniently by software. When it comes to depict the smallest geometrical details, users apply the native number of pixels of the camera detector. If the focus is more on the exact time lapse of a fast process, they use the high-speed mode and the associated higher frame rates. The results of both scenarios can then be overlaid in a suitable manner.

Binning technology enables to use a single camera for the analysis of different measurement scenarios, which previously might have required the use of several different thermographic cameras. The example of the ImageIR® 9400 camera series illustrates the wide range resulting from the latest development of InfraTec. Usually, full-frame images with (1,280 x 1,024) IR pixels at 180 Hz can be captured with this camera. Thanks to binning, in high-speed mode the frame rate for (640 x 512) IR pixels in the same FOV increases more than threefold to 622 Hz.

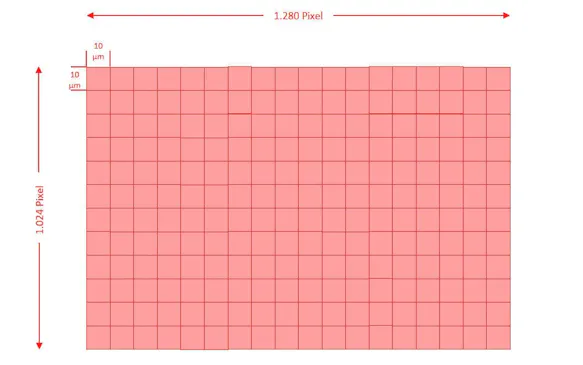

Pixel grid without high-speed mode

Pitch: 10 µm

Resolution: (1,280 x 1,024) IR pixels

Pixel grid with high-speed mode

Pitch: 20 µm

Resolution: (640 x 512) IR pixels

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.