Notebook-supported High-Speed Data Acquisition

Innovative and Secure Data Transmission Using 10 GigE Technology

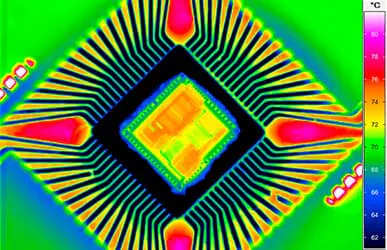

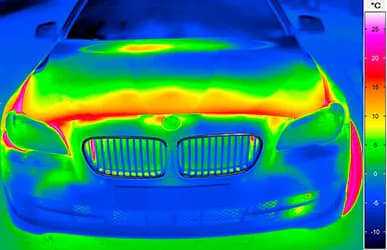

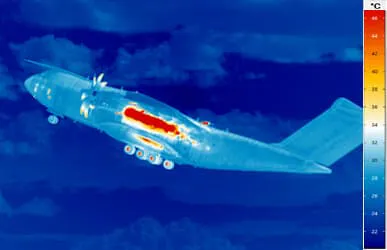

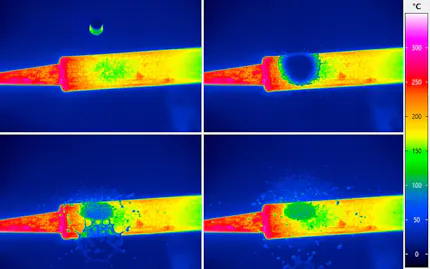

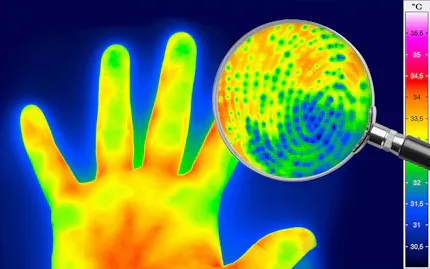

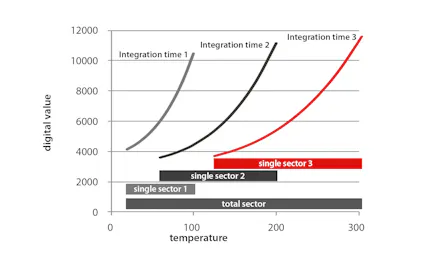

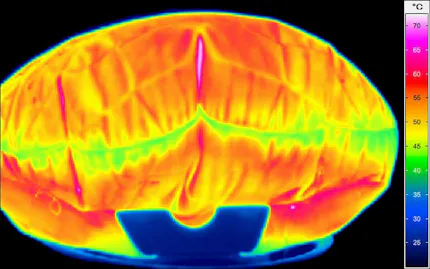

Thermographic systems are moving towards more and more increasing higher pixel numbers. Nowadays cameras are even available with detectors of up to (2,560 × 2,048) IR pixels. Not only the number of pixels has increased, but also the frame rates. For example, systems with cooled detectors (quantum detectors) can achieve full frame rates of approx. 1 kHz at an image size of (640 x 512) IR pixels. Even higher frame rates are expected in the future.

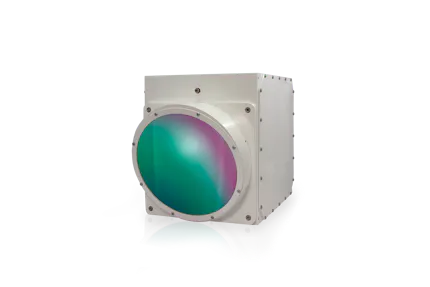

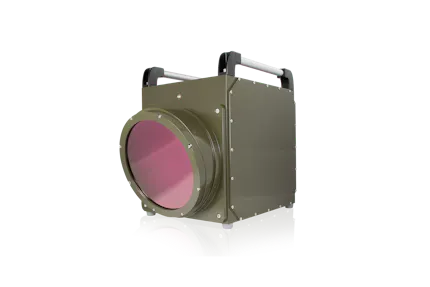

InfraTec offers the advantage of direct notebook-supported real-time data acquisition and processing. Therefore, it is absolutely necessary to achieve loss-free and reliable transmission of measurement data. Given that the advantages outweigh those of other data transmission technologies, InfraTec has decided to use the 10 GigE technology. InfraTec has raised this limit to about 1 kHz in VGA mode by means of an innovative and loss-free algorithm for data compression as well as the speed advantages of the 10 GigE interface in principle. Today's computer systems are capable of processing these data volumes without any loss. Even complex real-time image processing is feasible with these systems.

In addition, 10 GigE technology also allows secure and interference-free transfer of data generated at the highest frame rates and detector formats to a notebook computer. Thereby over several hundred metres can be bridged by using inexpensive and robust fibre optic cables (multimode). Thus, expensive and heavy CAMLink cables with limited cable length (maximum approx. 5 m) as well as expensive framegrabbers (only compatible with desktop PCs) are made a thing of the past. High-speed real-time data transmission eliminates all restrictions on system flexibility caused by limited camerainternal storage and likewise there is no need for expensive external storage media. In comparison, CoaXPress as an alternative would only allow cable lengths of approx. (30 … 40) m for the required data rates.

Overview of Advantages

Large quantities of measurement data can be stored directly on a standard notebook

Instant data transmission with the possibility of real-time processing

Uncomplicated data transfer over long distances feasible (up to several hundred metres)

Mobile system concept

Inexpensive, light, flexible and interference-proof transmission medium

Highest frame rates without the need of camera internal memory

No expensive Framegrabber required

Further developments of software, firmware and peripheral technology can be implemented independently of each other, ensuring that best in class technology can be deployed in every part of the system

In system solutions, an even higher degree of peripheral flexibility without impairing the image data throughput can be build up via individual interface solutions of a PC. This can be realised independently of the camera

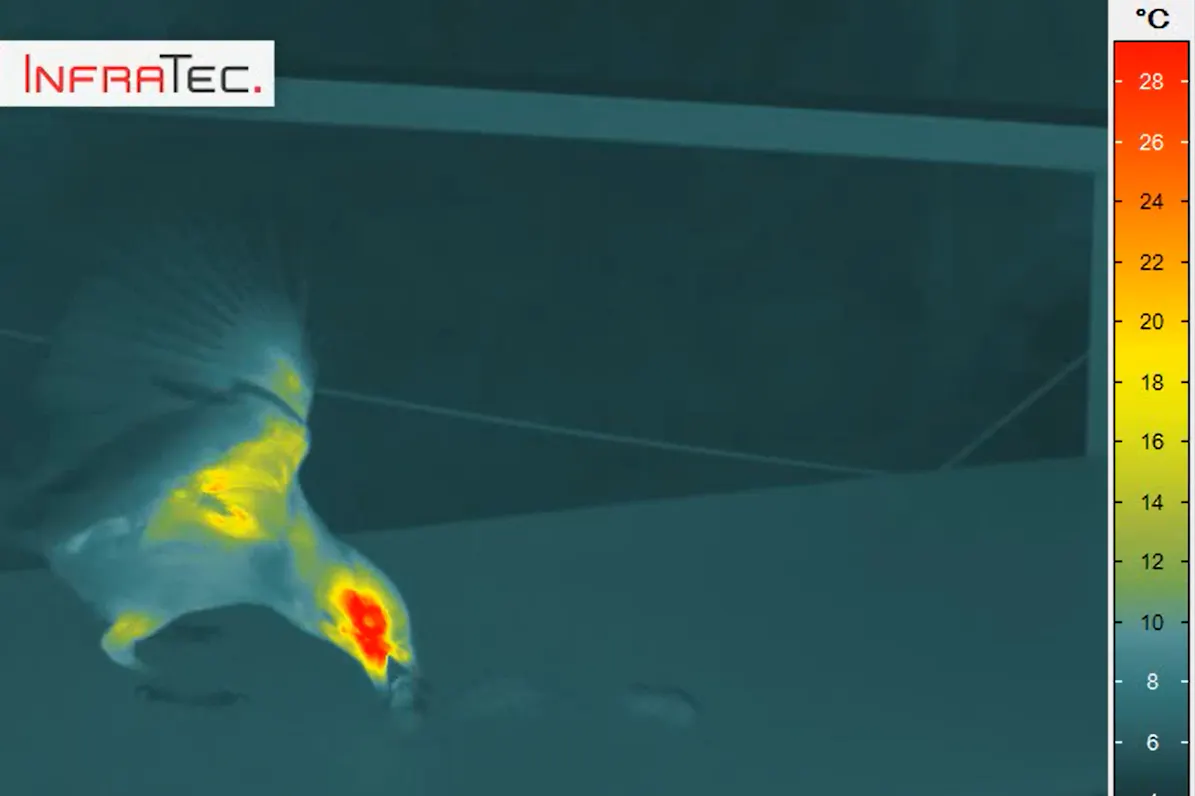

A Jays Fly Recorded with ImageIR® 8300 hp

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.