Fire Prevention - FIRE-SCAN

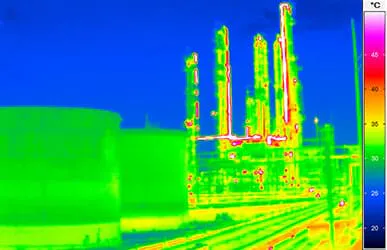

Fire protection with thermography solutions for companies and the environment

Surveillance of open areas and warehouses with fire detection and prevention systems

Thermal imaging cameras timely detect and locate critical temperature conditions

Contactless, high-resolution temperature measurement at great distances for early fire detection and prevention

Automatic documentation and alerting

Monitoring objects and fire even in case of smoke and dusty air

Thermography Systems for Early Fire Protection

Thermographic System FIRE-SCAN for Early Fire Detection

Early fire detection system FIRE-SCAN enables capturing of critical temperature indoor and on open-air grounds at an early stage and is optimised for early fire detection. An automatic calibration with threshold values results in prompt alerting up to automated fire fighting. However, should a fire break out, FIRE-SCAN provides an additional option for monitoring the area surrounded by fire even in case of smoke or formation of dust. Thus, fire fighting can be supported very effectively by the fire detection system.

High Thermal and Spatial Resolutions of Integrated Infrared Camera Assure Success

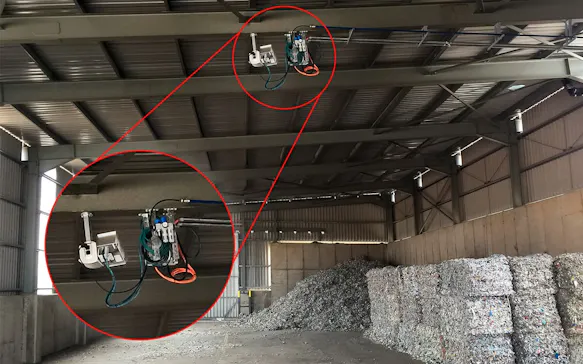

The application of high-performance infrared cameras for early fire detection systems allows a detection of smallest pocket of embers due to their high spatial resolution, meaning a sufficient number of pixels. In case of an insufficient number of pixels for the to-be-monitored area, it is possible to integrate further infrared cameras into the system FIRE-SCAN without any problems. The fire detection system’s sphere of action can be additionally expanded at a constant spatial resolution by mounting the infrared camera onto a remote-controlled Pan-tilt head. Besides the infrared camera’s spatial resolution, which meets highest requirements, the infrared camera system also features an optimised thermal resolution. Only this combination makes it possible to detect smallest temperature changes or hidden pockets of embers at an early stage. As may be necessary, this information will be displayed in control room or directly integrated into the available control system.

Early Fire Detection in Hazardous Areas: Systems with ATEX Certification

The fire detection system FIRE-SCAN is applied, for example, in the chemical industry. The development of explosive gas-air mixtures represents a central hazard there. Therefore, system components that have a certification in accordance with the ATEX Directive are used for such applications. These are primarily protective housings for thermal imaging and visual cameras, pan/tilt systems and electrical distribution systems. They are suitable for deployment in potentially explosive areas 1 and 2.

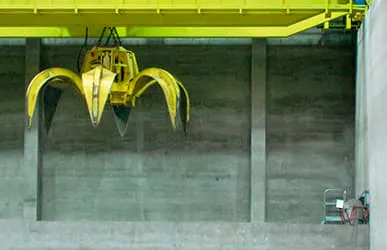

Thermographic Warehouse Monitoring for Fire Prevention

Thermography in early fire detection: challenges, important parameters and their influence

FIRE-SCAN for thermographic warehouse monitoring

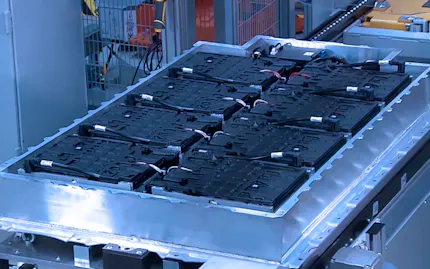

FIRE-SCAN for monitoring Lithium-ion batteries

High resolution infrared cameras with pan/tilt heads

Special infrared cameras for stationary installation

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

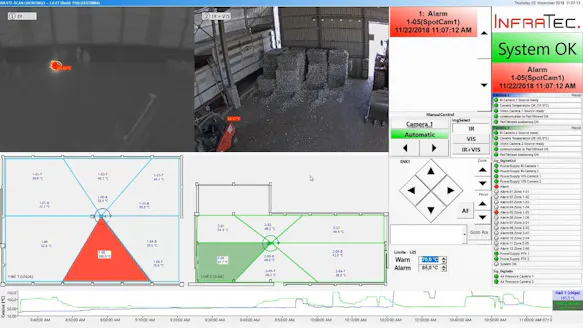

Powerful FIRE-SCAN-Software

Continuous display of current thermal images of all sections (mosaic-overview)

Simultaneous display of live image (thermal image and colour video)

Camera and system status indication

Merging of live images of thermographic and video camera

Recording of maximum, minimum and average temperature of each section

Single or multiple-camera system available

Graphics of temperature-time profile of all sections

Logging of operations

Filing of image data

Detecting and marking of sources of interference, e.g. wheel loaders

Alarm Release

Automatic alarm release when temperature values exceed critical thresholds

Multi-level alarm functions with adjustable warning and alarm threshold values

Analysis of long-term temperature trend with adjustable time basis

Documentation of alarm situations for analysing fire formation

Wide range of system versions due to modular design concept

Product Flyer

Get all the information you need at a glance in our product flyers

Use FIRE-SCAN for These Industries & Applications

Monitoring Seaports with Infrared Cameras

Monitoring ports brings with it a multitude of challenges. For example, a very large unclear area must always be kept completely in view. The goods of regularly arriving ships are also monitored for safety purposes during loading and unloading. Furthermore, the weather conditions – especially at seaports – are changing permanently.

Thermal imaging cameras effectively round off a complex security system in addition to visual cameras, security services, and ship and port personnel. They enable 24/7 monitoring, function even in the most adverse environmental conditions, allow the reliable measurement of temperatures of people and vehicles, infrastructure buildings and equipment, as well as cargo and stored goods even over long distances.

FIRE-SCAN is particularly suitable for monitoring mass and bulk materials in order to detect dangerous fire pockets or heating at an early stage. High geometrical resolution of the infrared camera in the monitoring system, combined with its installation on pan/tilt heads, allows targeted and detailed observation of particularly critical monitoring sectors in detail.

Advantages of FIRE-SCAN for Seaports Monitoring

Detection of heating before the fire occurs

Technical features: Use of radiometric zoom cameras, such as the VarioCAM® HD Z

This camera with optical 6x zoom allows you to keep an overview of large areas as well as to quickly zoom in on critical or conspicuous areas and immediately inspect them in great detail

Multiple cameras at different locations

Localisation of the slightest temperature changes even at great distances and in adverse visibility conditions

Powerful software with automatic alarm triggering when critical thresholds are reached