Infrared Thermography Applications “Kunststoff-Zentrum in Leipzig (KuZ)“

With infrared thermography, absolute temperatures, temperature distributions and relative temperature changes can be measured and tracked within dynamic conditions.

Due to relative good emission ratios of many plastics, infrared thermography is suitable for the extended characterisation of plastic processing technology and its optimisation. This application report exemplifies infrared thermography applications for plastic processing and inspection technologies at the KuZ.

InfraTec Solution

Kunststoff-Zentrum in Leipzig gGmbH

www.kuz-leipzig.de

Infrared camera

VarioCAM®-series

The infrared thermography is an adequate instrument for non-contact temperature measurements. In this way, absolute temperatures, temperature distributions and relative temperature changes can be measured and tracked within dynamic conditions. The capabilities of infrared thermography systems are multifaceted. As a result, applications in all kind of industries exist.

The most popular examples are:

Evaluation of thermal insulation of buildings

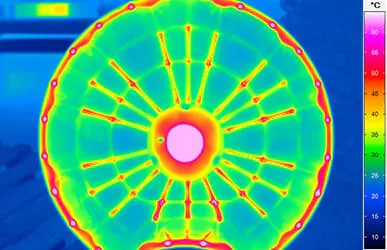

Determination of the performance of photovoltaic modules

Monitoring with infrared for easy fire detection

Inspection of spot welded joints for car body construction

Safety and object monitoring

Diagnosis of disease pattern in medicine

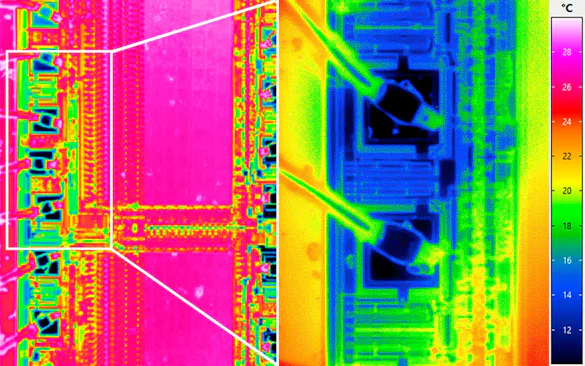

Quality management of electric/electronic components

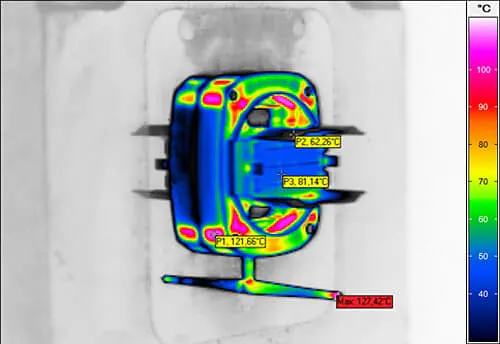

Cooling Performance of a Moulded Part during the Injection-moulding Process

The characteristics of an injection-moulded part are determined by the used plastic, geometry, and processing conditions. The cooling behaviour of the part inside the mould plays a major role. When the cooling effect happens too fast, for example, internal tensions can be frozen inside the moulded part. On the basis of attempts to get into the low-stressed condition, the moulded part could be seriously damaged during later applications. Furthermore, the cooling behaviour determines the crystalline structure of a partial crystalline thermoplastic material.

Due to a rapid cooling, the crystallization is restrained and therefore the crystallization is at its lowest level. On the other hand, if there is a slow cooling effect, a higher level of crystallization develops, which can have a positive impact on the mechanical properties. In this way the cooling process influences the morphology development of a plastic moulded part. In addition, the cooling down process also influences the shrinkage behaviour. Local temperature differences in a mould cavity cause differ-ent local shrinkage behaviour. This can lead to a deformation of moulded parts. In general, the cooling process plays a big role in the development of moulded part properties.

With the help of infrared thermography, the cooling process of an injection moulded part with different mould temperatures and total cooling times was analysed at the KuZ. The used material was PC/ABS. For IR recordings the thermographic system of the VarioCAM®-series of the company InfraTec was used.