ImageIR® 9100

High-resolution, radiometrically calibrated infrared cameras with a very good price/performance ratio - these are the new SWIR cameras from the ImageIR® series. They are suitable for temperature measurements from 300 °C and operate in the short-wave infrared range.

Detector operating in snapshot mode with (1,280 x 1,024) R pixels

Cost-effective, compact optics design with high imaging quality

The compact design and low weight predestine the SWIR thermal imaging camera for integration into existing system environments

The accompanying Software Development Kit (SDK) provides easy access to all camera functions

Efficient measurement of smallest details on large-scale objects

Flexible setting of temperature measurement ranges beyond factory calibration ranges

Wide temperature measuring range up to 1,700 °C

Highly accurate and repeatable measurements

Precise detection of smallest temperature differences

Smaller pixel sizes avoids geometrical measurement errors

Specialist for Measurement on Metallic Surfaces

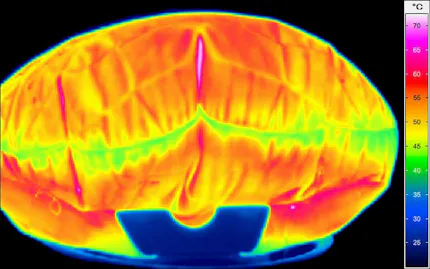

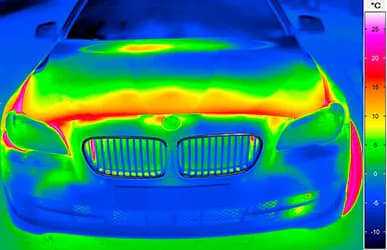

The high-resolution ImageIR® 8100 and ImageIR® 9100 are very compact thermographic cameras designed for stationary use, which work in the short-wave spectral range and are used preferably for contactless temperature measurement on metal surfaces because of their spectral characteristics.

Integration into Existing System Environments

Compact design and low weight make the ImageIR® 8100 and ImageIR® 9100 SWIR infrared cameras ideal for integration into existing system environments. With the associated Software Development Kit (SDK), all functions of the cameras are easily accessible. Due to their robustness, they can also be used in adverse environmental conditions, for example in industry.

Long-term Stability

The cameras do not require a mechanical cooler and are suitable for maintenance-free continuous operation. With the new SWIR cameras from InfraTec, users thus receive thermographic cameras that are equipped with high measurement accuracy as well as very good short- and long-term stability.

Smal Pitch Dimension

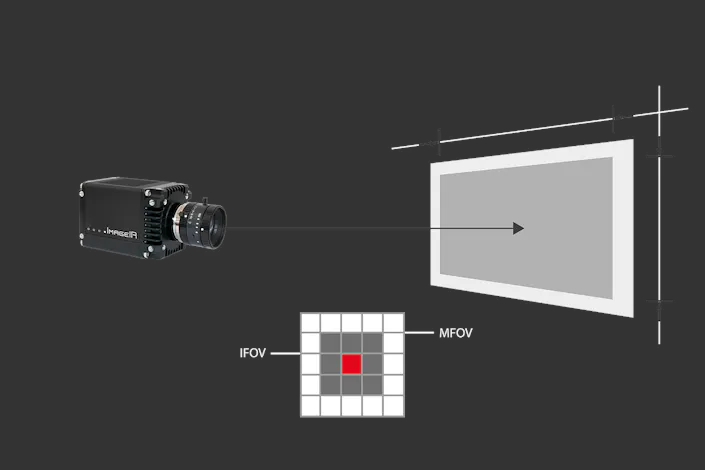

They have a pixel pitch of only 5 μm, resulting in a small detector chip diagonal. This in turn allows a comparatively affordable and compact optical design with high imaging quality. In combination with radiometric calibration, brilliant thermographic images with high geometric and thermal resolution can thus be achieved in both formats. In SXGA format, even the smallest details on large-area objects can be optimally resolved. Adaptation to real measurement scenarios is very convenient thanks to the interchangeable lenses with different focal lengths.

Do You Want to Know More About the InfraTec Service?

Our experienced service team will be happy to assist you.

Technical Specifications of ImageIR® 9100 Series

| Spectral range | (0.9 ... 1.7) µm |

| Pitch | 5 µm |

| Detector | InGaAs |

| Detector format (IR pixels) | (1,280 x 1,024) |

| Image recording principle | Snapshot |

| Readout mode | ITR / IWR |

| Temperature measuring range | (300 ... 850) °C, up to 1,700 °C* |

| Measurement accuracy | ± 3 % |

| Temperature resolution at 30 °C | Better than 1 K (Temperature resolution at 350 to 1,000°C) |

| Frame rate | Up to 83 / 181 / 341 / 2,262 Hz |

| Window mode | Yes* |

* Depending on model

** In selected measurement ranges

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

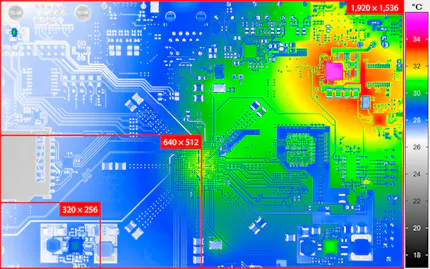

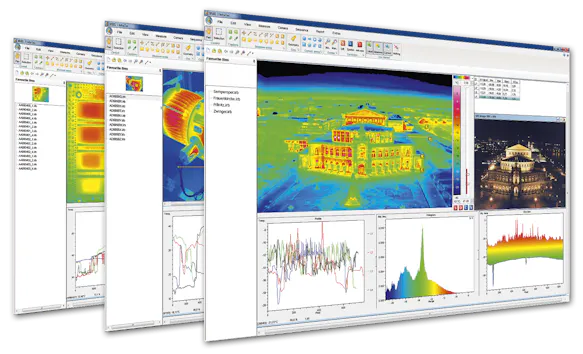

Comprehensive Thermography Evaluation Software for Efficient Operation

The software family IRBIS® 3, which was developed by InfraTec, is part of a complete system of the camera series ImageIR®. The comfortable and professional thermography software IRBIS® 3 professional offers a wide range of analysis- and editing tools to analyse sophisticated thermal investigations. The combination of ImageIR® together with the professional thermographic software meets all requirements that are set as standard for efficient high-performance tools for thermographic investigations.

Product Flyer

Get all the information you need at a glance in our product flyers

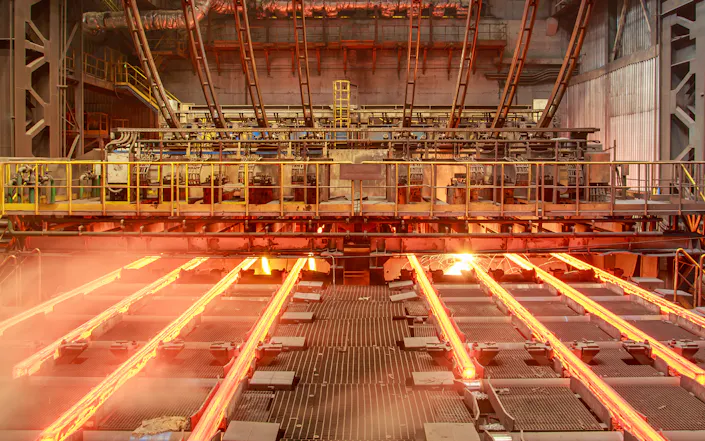

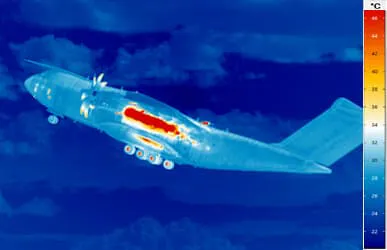

Industries & Applications for the SWIR Infrared Camera Series ImageIR® 9100

Some thermographic measurement tasks are characterised by very high temperatures and challenging materials. They can only be solved with a high degree of uncertainty in the medium (MWIR) and long-wave (LWIR) infrared range, with regard to the occurrence of measurement errors. InfraTec‘s SWIR infrared cameras ImageIR® 8100 and ImageIR®� 9100 offer new possibilities. They expand the portfolio of thermographic temperature measurement and allow for example emissivity-optimised measurements of temperatures on metallic surfaces.

Further Application Areas

High-temperature applications (for example hot forming processes, heat treatments)

Metal industry (for example welding processes, press hardening, brazing, forging)

Additive manufacturing and laser applications

Ceramics and glass industry

Signature recognition and measurement

Solutions for integration

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.