ImageIR® 6300

The ImageIR® 6300, as an extension of the ImageIR® series, offers entry into the class of infrared cameras with cooled photon detectors and provides users with enormous performance advantages at a very good price/performance ratio. Due to the latest SWaP detector technology and a robust, very compact construction, this camera is predestined for demanding OEM and continuous operation applications.

Pixel pitch of 10 µm

Predestined for demanding OEM and continuous operation applications

Wide range of different interchangeable camera lenses available

Easy and economical installation in harsh process environments

Large detector enables highest sensitivity

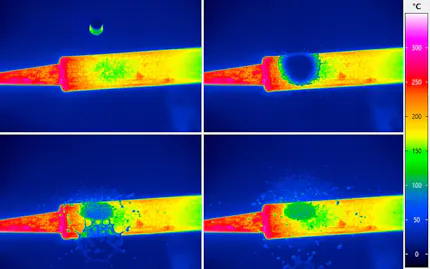

Analysis of extreme temperature changes and gradients in full frame

Control via web interface

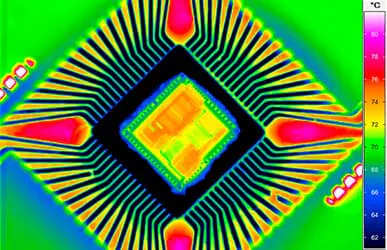

Precise detection of smallest temperature differences

High-speed Mode: Increase frame rates up to 620 Hz and thermal resolution at the same time using binning technology

Enables the maintenance-free use over long operating times

Technical Specifications

| Spectral range | (3.7 … 4.15) µm |

| Pitch | 10 µm |

| Detector | xBn |

| Detector format (IR pixels) | (640 x 512) |

| Image recording principle | Snapshot |

| Readout mode | ITR / IWR |

| Aperture ratio | f/3.6 |

| Detector cooling | Stirling cooler |

| Temperature measuring range | (-10 ... 600) °C |

| Measurement accuracy | ± 2 °C or ± 2 % |

| Temperature resolution at 30 °C | Better than 0.03 K / 0.02 K in high-speed mode |

| Frame rate | Up to 180/344/619/2.760 Hz / High-speed mode: 620/1030/1500/2150 Hz |

| Window mode | Yes |

* Depending on model

** In selected measurement ranges

Small Pixel Pitch

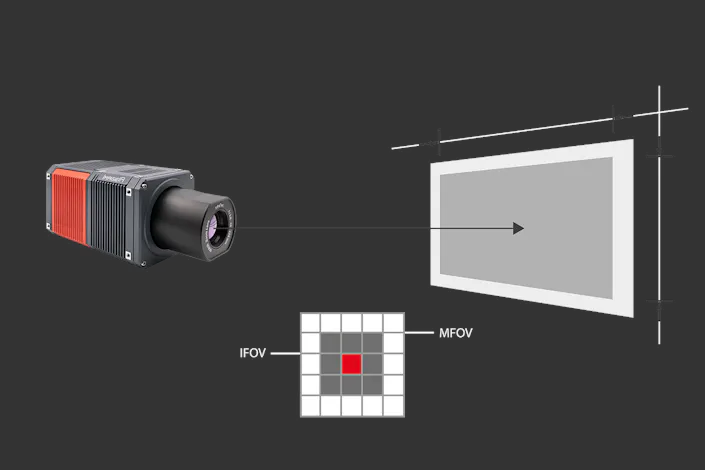

The radiometrically calibrated system camera ImageIR® 6300 is equipped with a cooled focal plane array photon detector of the latest generation. By combining the detector format of (640 × 512) IR pixels with the very small pixel pitch of 10 µm, the camera delivers razor-sharp images. Due to its snapshot mode, moving objects can also be displayed without distortion. The innovative XBn detector technology allows the detector to be operated at a significantly higher working temperature than the usual approximately 80 K.

Its pixel pitch of only 10 µm gives the system camera a comparatively small pixel size. This allows for a compact optical design while maintaining high image quality. In combination with radiometric calibration, most precise measurement results can be achieved. With an optionally available integrated solid state drive (SSD), large amounts of data can be stored directly on the camera.

The ImageIR® 6300 is the first model in the ImageIR® series to feature a new integrated operating system. This opens up a wide range of new functions, such as fully autonomous camera operation without the need for an additional control PC. The camera can also be controlled via a web interface using a smartphone or tablet. In addition, users can run their own software directly on the camera and access the data stream directly via the integrated SDK. Together with the option of power supply via a wide-range input (9–36 V) or Power over Ethernet (PoE), these features make the the infrared camera much easier to use. This is particularly true for plant-integrated applications and in hard-to-reach places.

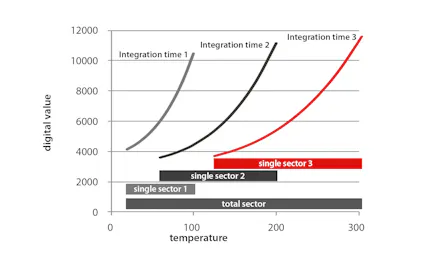

Measurements with the ImageIR® 6300 can be carried out at two speeds. In normal mode, the camera achieves full frame rates of up to 180 Hz. With the binning function, the frame rate can be increased by more than three times to up to 620 Hz. This is made possible by combining four detector pixels into a single one. Thereby the sensitive pixel area is increased to compensate for the shorter integration times, and the readout of the pixel data is accelerated. At the same time, the thermal resolution improves by a factor of two in high-speed mode. Even higher frame rates can be achieved by reducing the field of view to freely definable subframe modes.

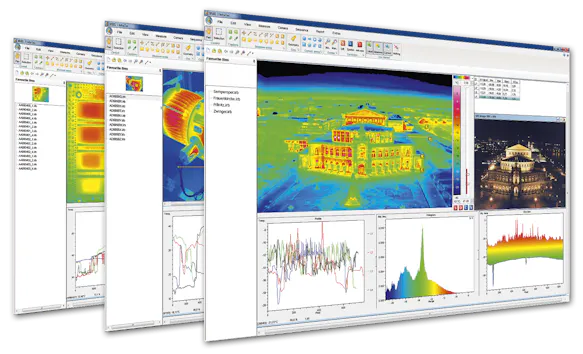

Comprehensive Thermography Evaluation Software for Efficient Operation

The software family IRBIS® 3, which was developed by InfraTec, is part of a complete system of the camera series ImageIR®. The comfortable and professional thermography software IRBIS® 3 professional offers a wide range of analysis- and editing tools to analyse sophisticated thermal investigations. The combination of ImageIR® together with the professional thermographic software meets all requirements that are set as standard for efficient high-performance tools for thermographic investigations.

Do You Want to Know More About the InfraTec Service?

Our experienced service team will be happy to assist you.

Comprehensive Range of Optics Enables Wide Variety of Applications

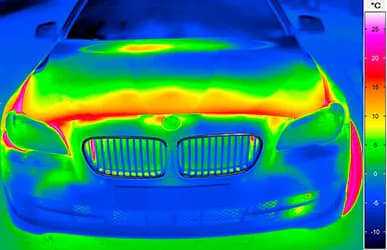

Thanks to the wide range of different interchangeable camera lenses available (12 mm, 25 mm, 50 mm (with an optional 300 mm close-up), 1x microscope), the ImageIR® 6300 can be optimally configured for a wide range of applications, from inline inspection to laboratory test stations. Within this camera series, the ImageIR® 6300 Z is available with a standard integrated 7.5x zoom lens and optional teleextender.

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.