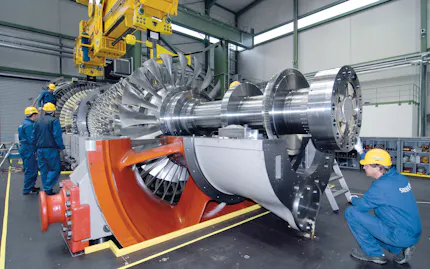

Thermal Optimisation of Components and Assemblies

Improve product features and process characteristics based on energy optimisation

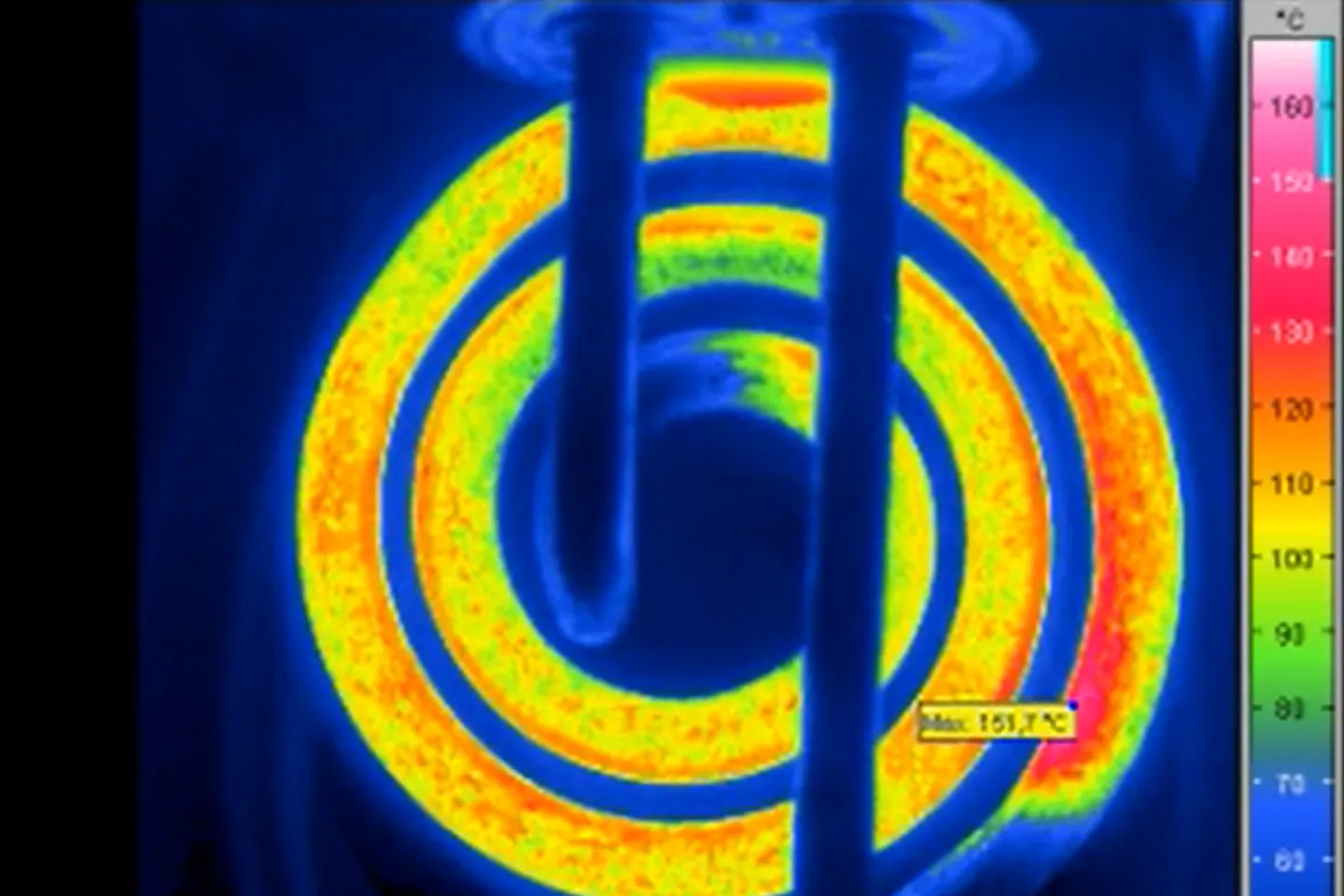

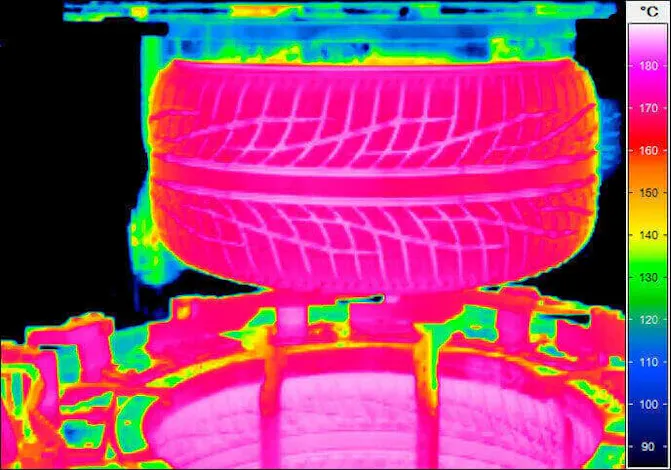

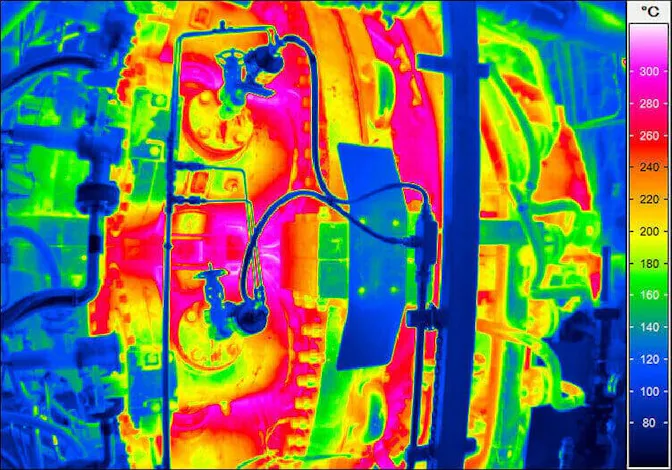

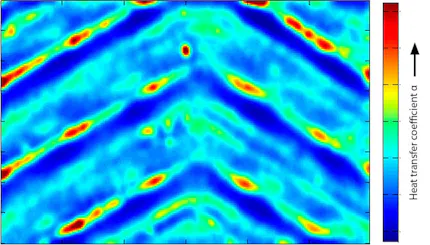

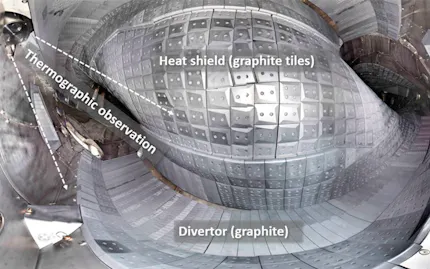

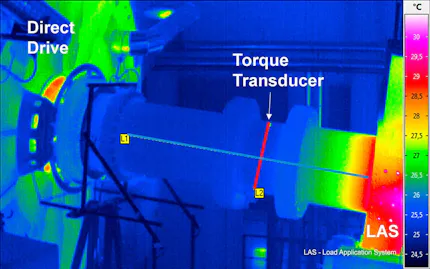

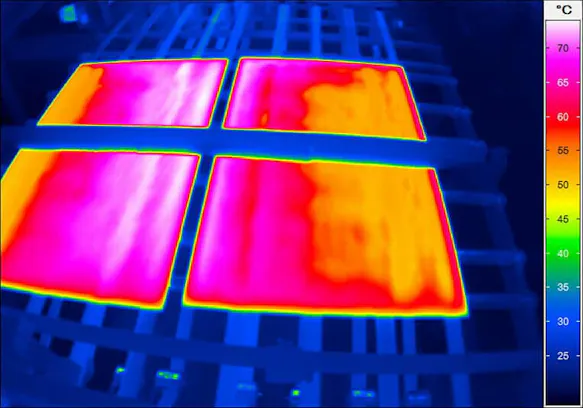

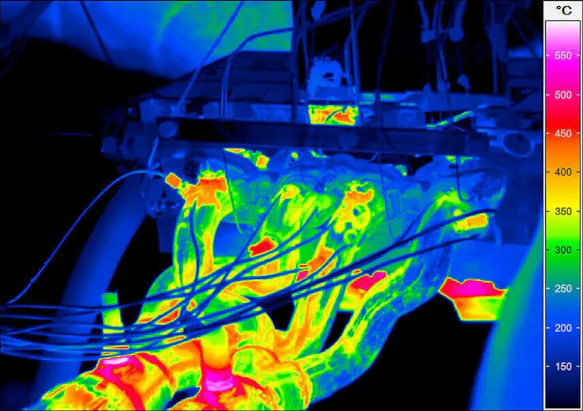

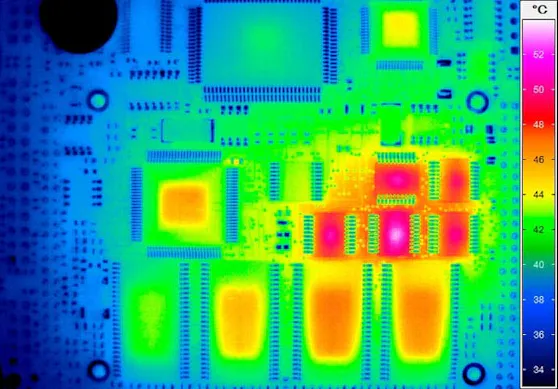

Thermal images allow for detailed analysis of heat developments of components and processes

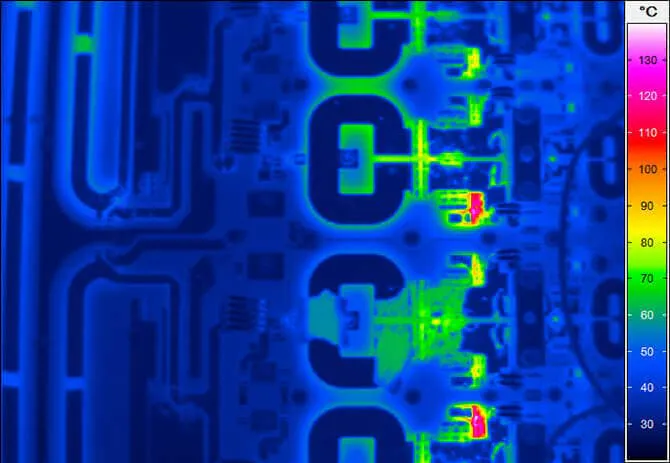

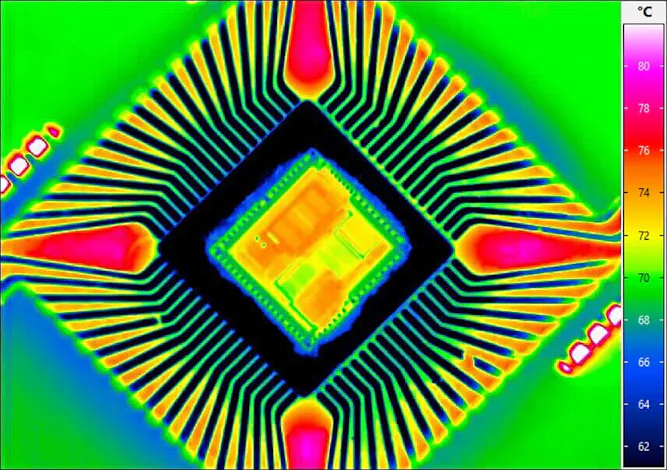

Hot spots may indicate faults and room for optimization

High number of pixels of infrared cameras prevent risk of wrong measurements

Heat as One Important Energy Factor Can Be Controlled

All manufacturing of goods needs energy input. Energy will also be released or used when using products. As most of this energy comes in the form of heat it is most important for the optimisation of manufacturing processes as well as for the product development itself that the effect of heat can be analysed the best way.

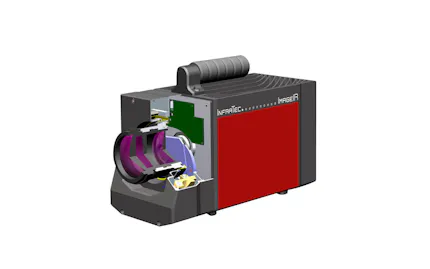

Infrared camera systems can do this in a very good way as firstly they do not need any contact for the measurement and secondly they provide an image of the heat distribution. This helps to visualize and understand the situation. Also the thermographic software family IRBIS® 3 supports this. A variety of analysis methods precisely present temperature changes over time and in space.

Flow Analysis Using Thermal Imaging

General information about infrared thermography

Presentation of different infrared camera techniques

Presentation of different flow types and how to measure them with thermography

Demonstration of different application possibilities, e.g.: aerodynamic optimisation, heat management industry, environmental research, geological research

Applications for Thermal Imaging on Wind Power Systems

General information about infrared thermography and presentation of different infrared camera techniques

Monitoring wind turbine power plants by (passive) thermography

Principle & methods of active thermography and examples

Optimisation of Components or Processes by Heat Input or Drainage

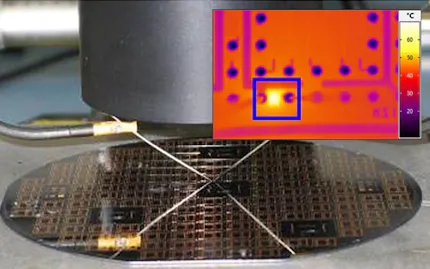

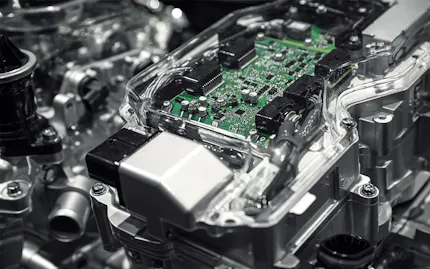

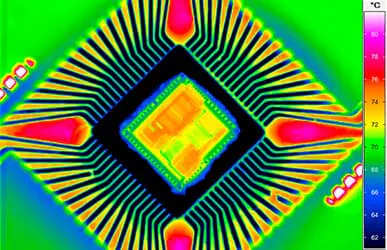

If thermal imaging indicates hot spots at a PCB there are temperatures with a specially high temperature and this could indicate problems. If this is a normal temperature the heat drainage might still be improvable. Like this overheating of components or bordering components could be prevented. To detect the hot-spots a sufficient geometrical resolution is crucial. Only details which are well resolved by a sufficient number of pixels can be measured correctly. Therefore high-resolution infared camera systems by InfraTec are first choice for usage in product development.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

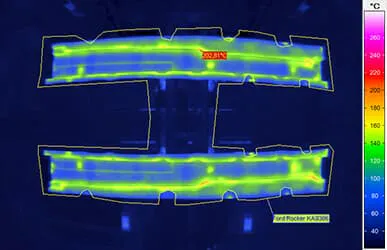

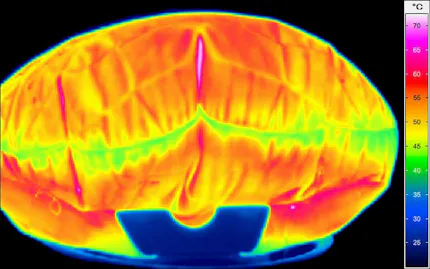

Heating of a Heating Coil