Infrared Cameras for Plant Inspections

Thermal imaging increases plant productivity, work safety and product quality

Condition based preventive maintenance is most cost efficient

Thermography allows inspections of a wide range of faults

Imaging solution provides first indications at the place of inspection

Tracing of condition of assets over time possible

Efficient reporting with integrated thermographic software

Thermography is the Most Flexible Method of Predictive Maintenance

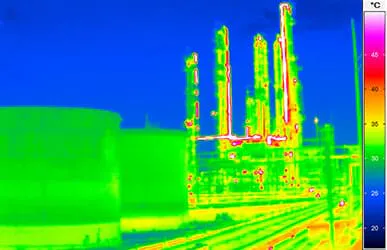

Increasing capital intensity and a growing interlinking of production chains require a steadily increasing availability. Predictive and conditions based maintenance greatly contribute to this. The right operation of the production facilities furthermore secures a high product quality, a higher production throughput and of course also the life span of the facilities themselves will be prolonged. Enterprises are more and more focused on energy usage and therefore a higher energy consumption caused by a non-optimally maintained facility is considered a serious drawback.

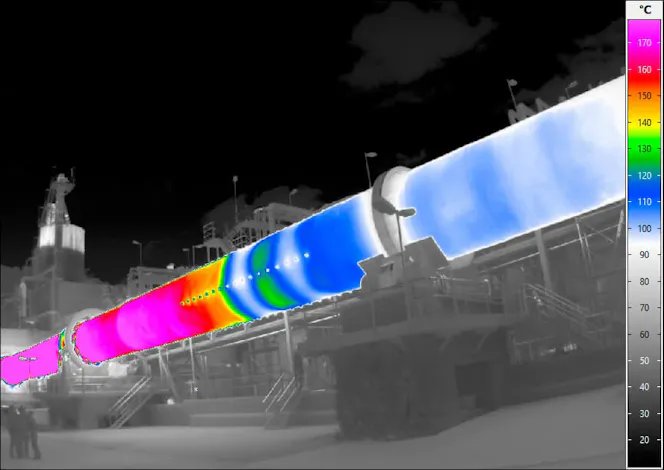

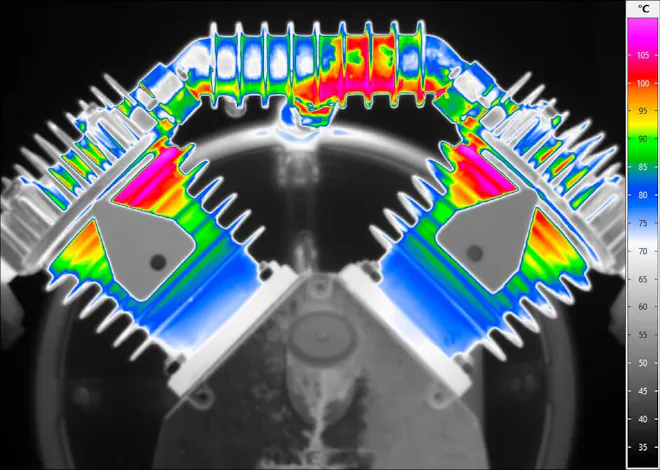

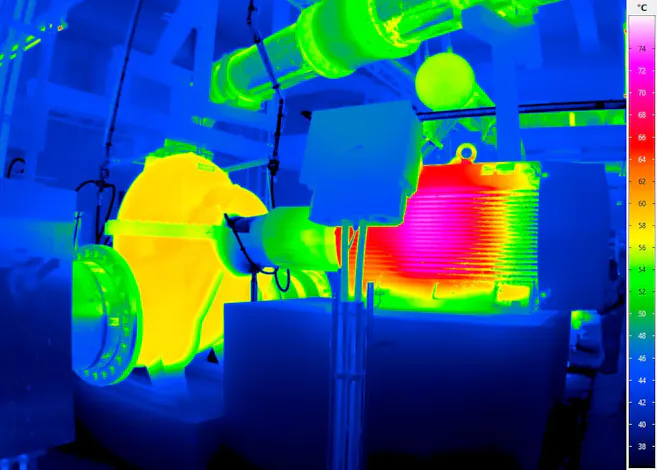

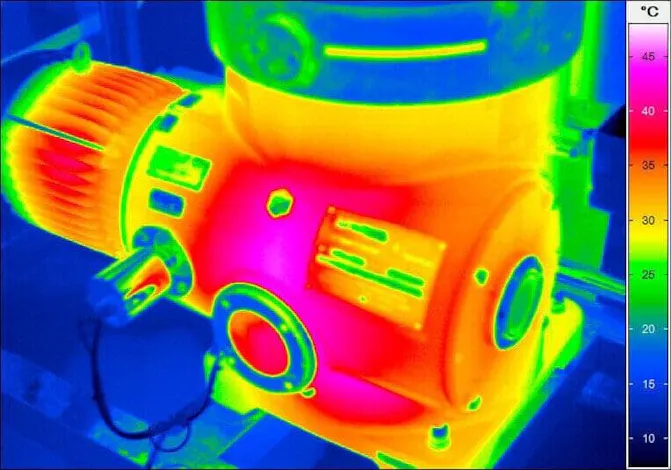

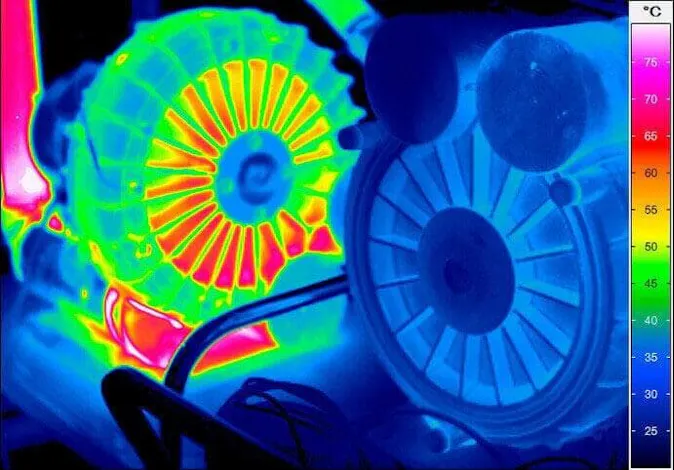

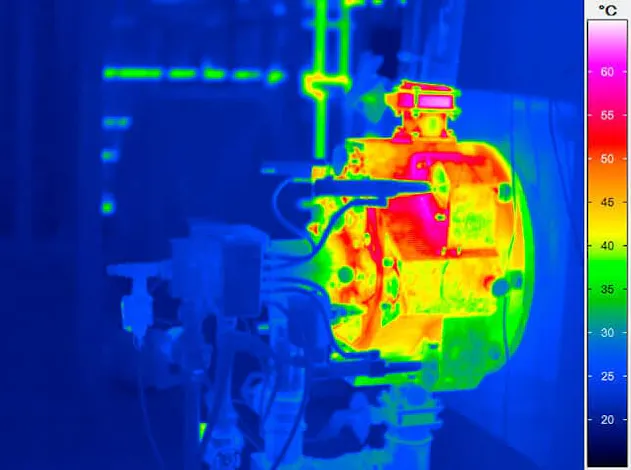

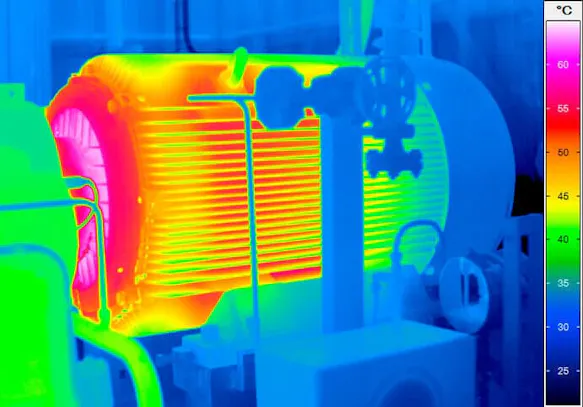

As people are the most important production factor work safety needs to be focussed on the most. Predictive maintenance takes care of work safety. Thermography as a method of predictive maintenance can be used for pinpointing on a wide range of faults - in electronics, in lubrication, in positioning of spindles or heat exchangers. Thereby thermography contributes a lot to the success of manufacturing companies.

Infrared Camera Systems Provide for Efficient Inspections by Visualisation and Alarming

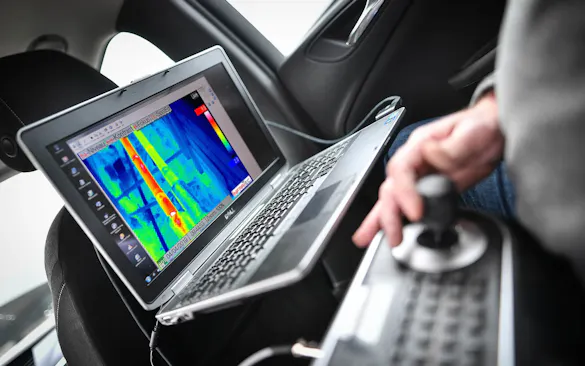

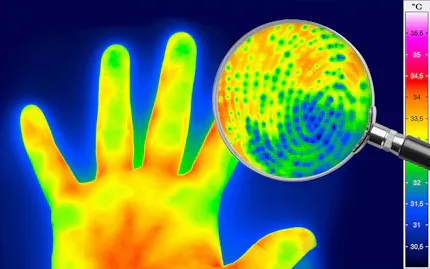

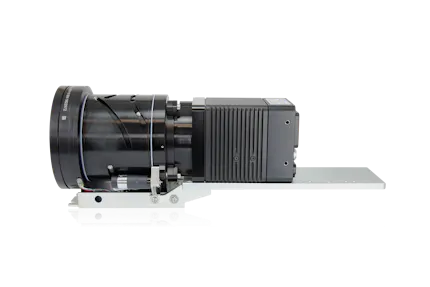

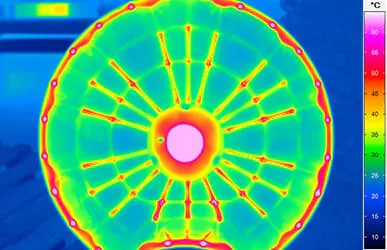

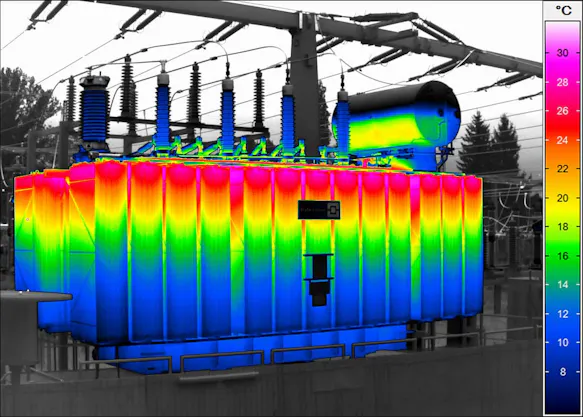

Special advantages of infrared camera systems in predictive maintenance result from the non-contact temperature measurement. Thereby the behaviour of the facility will not be influenced by the checks. Maintenance personnel is also only exposed to smaller risks during inspections. Additionally the inspectors receive a visualisation of the temperature distributions within the field of view as well as an automated alarming when surpassing temperature thresholds. That´s why they can already get a good first overview of the condition on site. As additionally the thermographic data can be easily stored it is possible to monitor the condition of the facilities over time and determine the best timing for any necessary maintenance.

Applications for Thermal Imaging on Wind Power Systems

General information about infrared thermography and presentation of different infrared camera techniques

Monitoring wind turbine power plants by (passive) thermography

Principle & methods of active thermography and examples

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

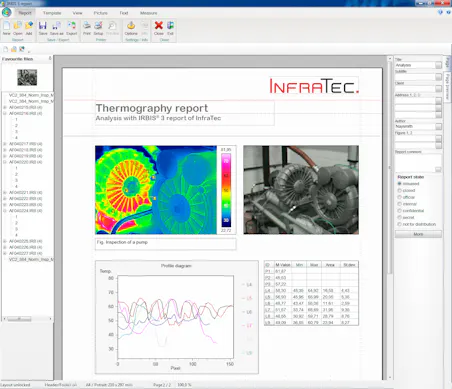

Fast Reporting of Essential Inspection Results

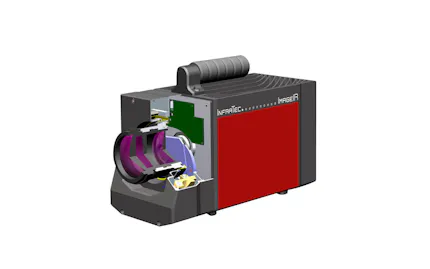

A big advantage of infrared camera systems for companies is the easy handling and the low maintenance needs. Especially the cameras of the VarioCAM® HD series come with a rugged design making them most suitable for usage in rough industrial environments. The thermographic software IRBIS® 3 provides efficient analysis of thermographic data and reporting for the transfer of crucial inspection results.