Thermographic Monitoring of Solar Power Tower – SPTC

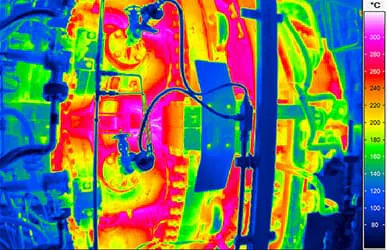

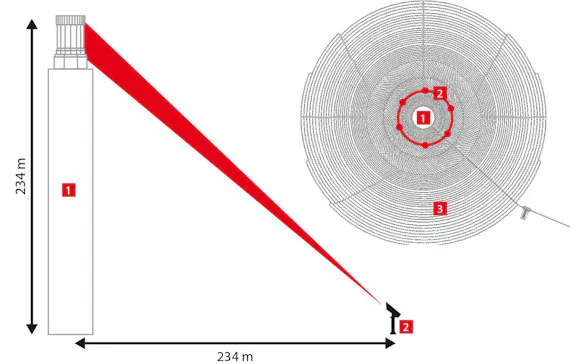

Solar power towers also named concentrated solar power tower – power plant – CSP plants belong to the category of solar-thermal power plants whose basic principle relies on the absorption of direct radiation from the sun and its conversion into thermal energy. This takes place in a highly effective absorber, which is located in the upper part of a solar power tower of up to 250 metres in height. Around the solar power tower on the floor, thousands of motorized, movable mirrors (so-called heliostats) are arranged in concentric circles, which are aligned permanently by a control system in such a way that the solar radiation concentrates on the absorber as optimally as possible.

This heat energy is normally conducted from the absorber by liquid salt as a carrier medium and used to generate steam for the subsequent generation of electricity with conventional steam turbines and generators by means of a heat exchanger.

The very good storage capacity of this hot, liquid salt as a heat-transfer medium offers great benefit compared to other forms of solar energy generation by the fact that the generation of electrical energy can take place continuously.

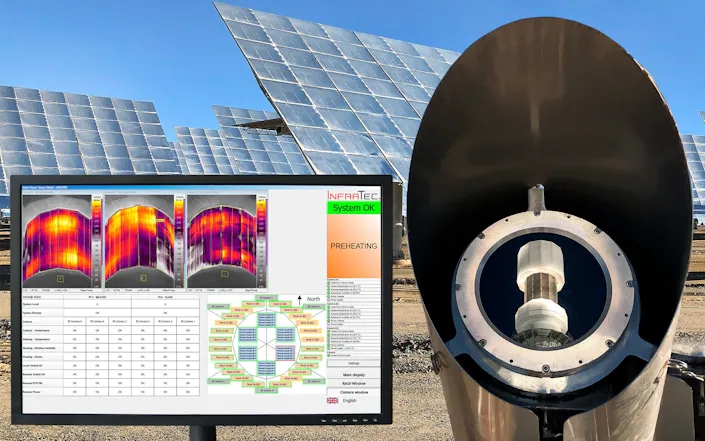

With Solar Power Tower Check (SPTC) for CSP plants (concentrated solar power) InfraTec offers a high-performance system for fully automatic remote monitoring of the surface temperature for the entire absorber of a solar tower. SPTC works on the basis of infrared thermography technology and provides important measurement data reliably for optimum and safe operation of a key point of the solar power tower.

System Features

Multi camera system for fully 100 % monitoring of absorber surface

Highly detailed measurement of the panel temperature of the absorber

Extensive conditioning of live images through automated focus tracking, size rectification and image stabilization

Redundantly designed hardware and software for the entire system

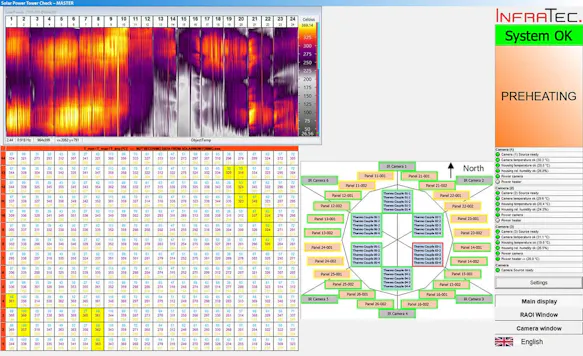

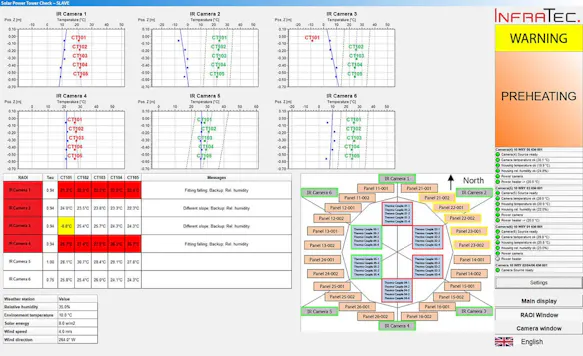

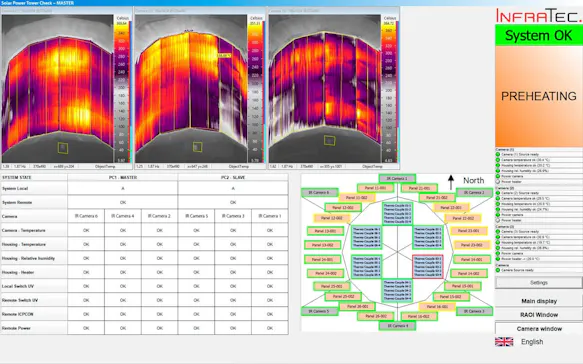

Main display with options for parameter setting, monitoring, operation, display, evaluation & playback with SPTC software

Clear graphics with temperature values of the entire absorber surface, warning or alarm values in a table

Continuous and fast transfer of all temperature and system data to the central power plant control system

Customised system alignment and adjustment

Benefits of the SPTC System

Automatic and complete absorber temperature monitoring on 24 / 7 basis

HD thermography cameras and optimised tele lenses guarantee long-term precise and reliable temperature measurements via long distance

Reduction of maintenance costs and downtimes

Continuous real-time measurement and temperature analysis

Redundant design of the complete system for safe operation

Complex compensation of environmental influences

Reliable alerting with defined limit values

Specialised temperature measurement algorithm and software with interface to main operator system

Optimised system for commissioning and regular operation of CSP solar power tower plants

Optional remote access

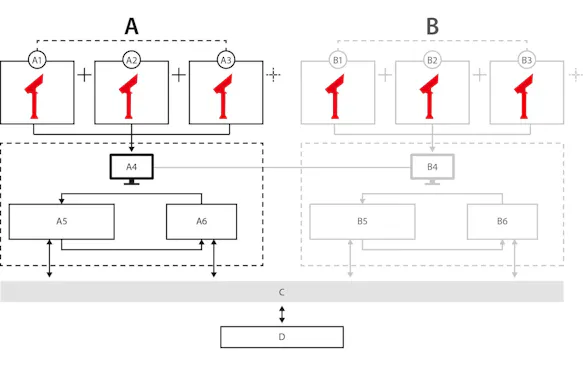

System Structure of Hardware and Software Components

A – Master system

A1 ... A3 – IR camera (in protective housing with junction box)

A4 – PC 1

A5 – Temperature correction software

A6 – SPTC software

B – Slave system

B1 ... B3 – IR camera (in protective housing with junction box)

B4 – PC 2

B5 – Temperature correction software

B6 – SPTC software

C – Modbus TCP / IP

D – Central control system

Automated Monitoring of Thermal Solar Power Tower/CPS Plants by Means of Thermography

The absorber tubes of a solar tower power plant are heated up intensely by the concentrated solar radiation of the heliostats during operation. The SPTC measures the resulting temperatures and their local distribution on the absorber panels without any interaction of an operator. The system transfers the measured values to the control system, which calculates the signals for controlling the individual heliostats. In this way, optimum absorption behaviour is set, which ensures the efficient operation of the plant.

Corresponding limit values resulting in automatic warnings if they are exceeded, can be defined for monitoring the temperature development of the entire solar absorber and for preventing overheating.

Highly reliable components and a flexible structure characterise the turnkey SPTC monitoring solution. Thus, it can be easily adapted to the different conditions and system environments in the solar power tower.

Components

HD thermography cameras with highest resolution of (1,024 × 768) IR pixels

Rugged 19"-industrial standard main cabinet

Protective housing designed to withstand extreme environmental conditions

Decentralised installable components (IR-cameras, PC, alarm unit), fiber optic cable for interference-free data transmission

TCP / IP based flexible structure

Highly redundant transmission adjustment based on different measurement methods

Redundant power supply, data transmission, complete data exchange via master and slave PC

Easy to use SPTC software allows flexible customisation

Software

Composite thermal image of the measurement range of the absorber surface and display of the temperature values

Data analysis to align the transmission and evaluate the state of the associated components

Live view of IR cameras with status overview of redundant system components

Product Flyer

Get all the information you need at a glance in our product flyers