Quality Control for More Precision in Press Hardening and Hot Forming – PRESS-CHECK

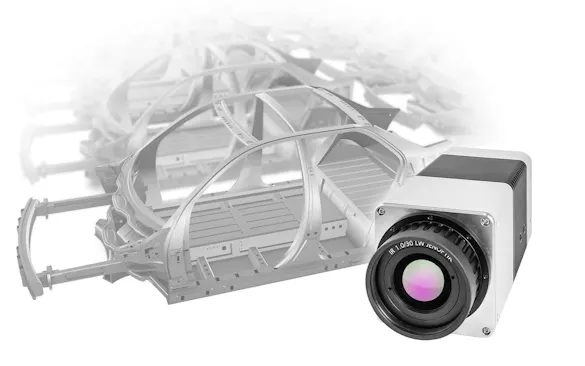

InfraTec´s PRESS-CHECK automatically monitors and records position and temperature distribution of parts during press hardening and hot forming and thereby facilitates meeting CQI-9 standard requirements in the automotive industry and can prevent expensive tool damage.

Quality Control with PRESS-CHECK

Automatic sorting of sheets, detection of misplacement and press shut down if necessary

Logging and evaluation of all collected data and reporting to the master control system via industry-standard interfaces

The flexible structure and data interface make InfraTec´s PRESS-CHECK easy to integrate

PRESS-CHECK: For End-to-end Quality Control and Trouble-free Operation During Press Hardening

Thermography in Use in Press Hardening and Hot Forming

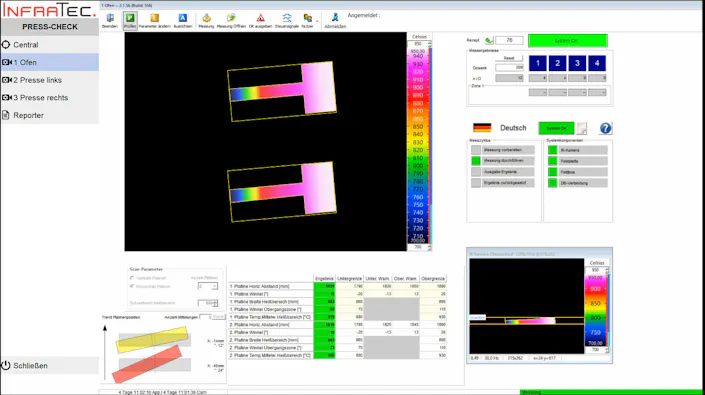

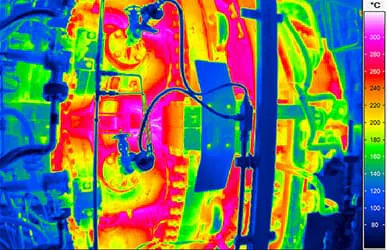

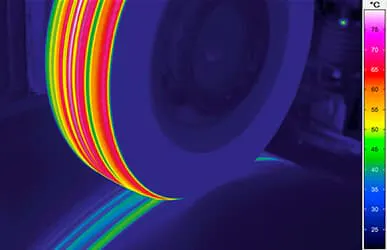

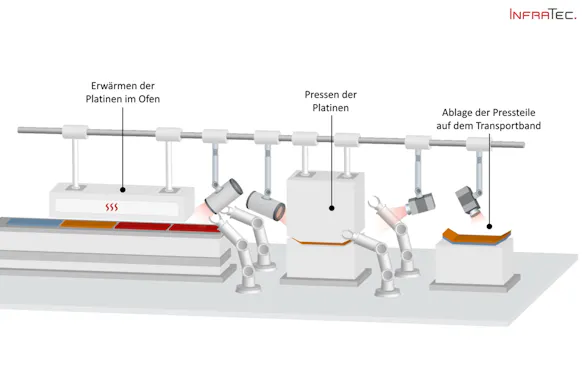

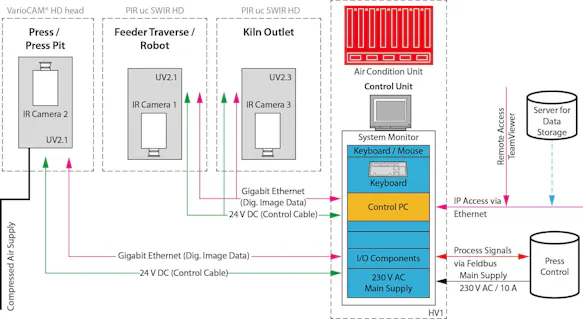

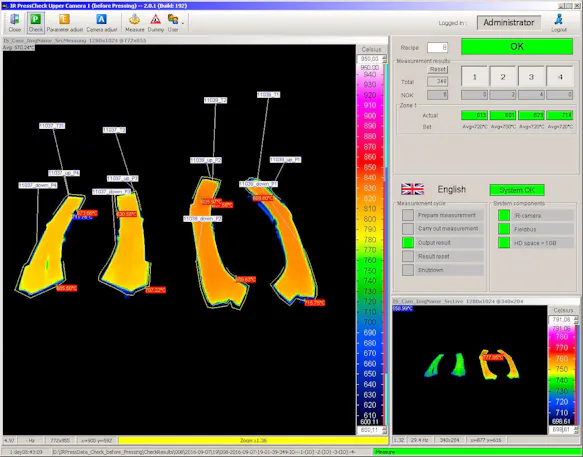

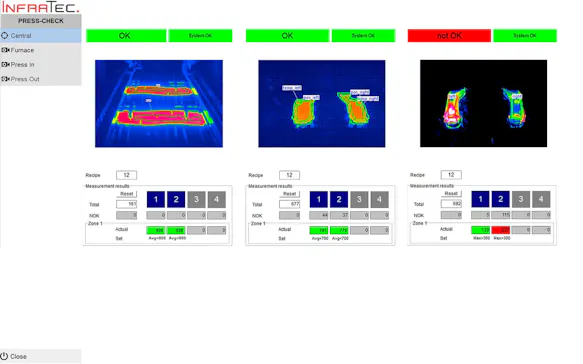

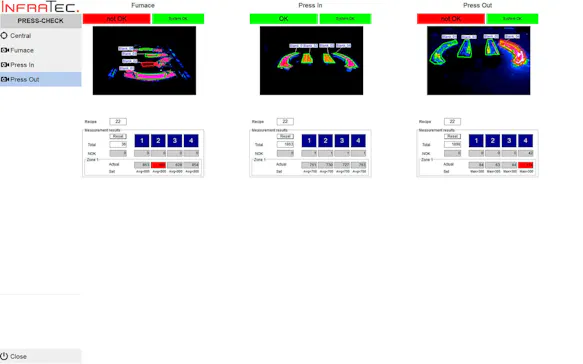

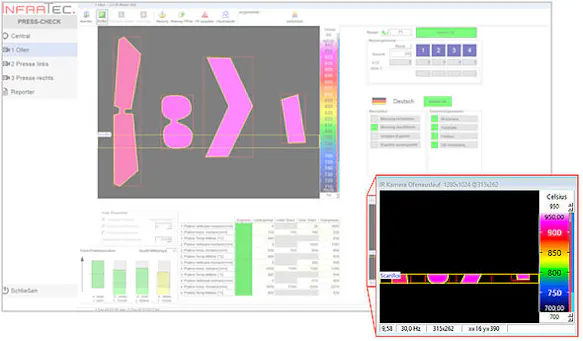

The automated test system PRESS-CHECK works with two or more powerful high-resolution infrared cameras for continuous measurement of the two-dimensional temperature distribution on the parts before and after the hot forming or hot press stamping process, ultimately enabling full compliance with the specified thermal process parameters.

As a result, you manufacture parts with the designed microstructure and a corresponding local hardness distribution. The thermographic-based, two-dimensional monitoring of process temperatures during the hot forming or hot press stamping process ensures a consistently high production quality, with distinct advantages over merely selective temperature measurements on reference points offered by pyrometers, for example.

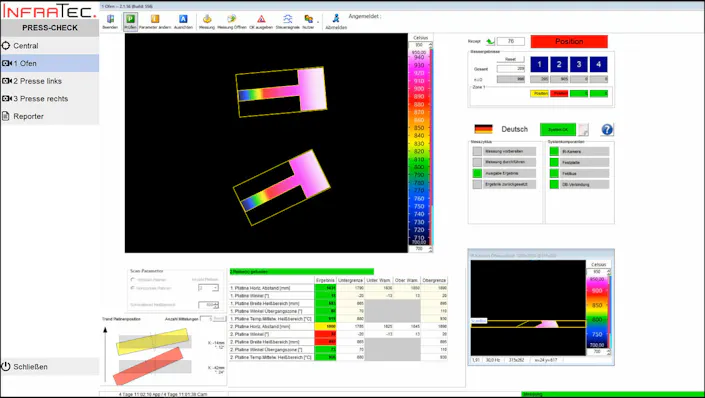

The process-specific temperature limits for the differently shaped metal parts can be managed in special parameter sets, also called recipes. Stampings with different thermal signatures during the hot forming process are recognised and can be automatically sorted out, so your wastage rates fall considerably. Furthermore, the system checks whether the sheets are placed into the press in the expected number and correct position. In doing so, it can also detect blanks that are incorrectly placed on top of each other (double sheets). If necessary, the press can be stopped automatically, e.g. to avoid expensive damage to the tools.

PRESS-CHECK is linked to the supervisory control system of the respective press, and transmits data as well as the classification of all pressings in real time, thus avoiding slowing down of the hot forming process. With InfraTec´s PRESS-CHECK you can manage the various molds and associated parameter sets automatically, even creating logs. This makes InfraTec PRESS-CHECK universally usable for all applications running on the press without the need for additional equipment and setup time. With highly reliable components, special protective housings, a flexible design and industry-standard data interfaces, the PRESS-CHECK test system can be easily integrated in your press processes.

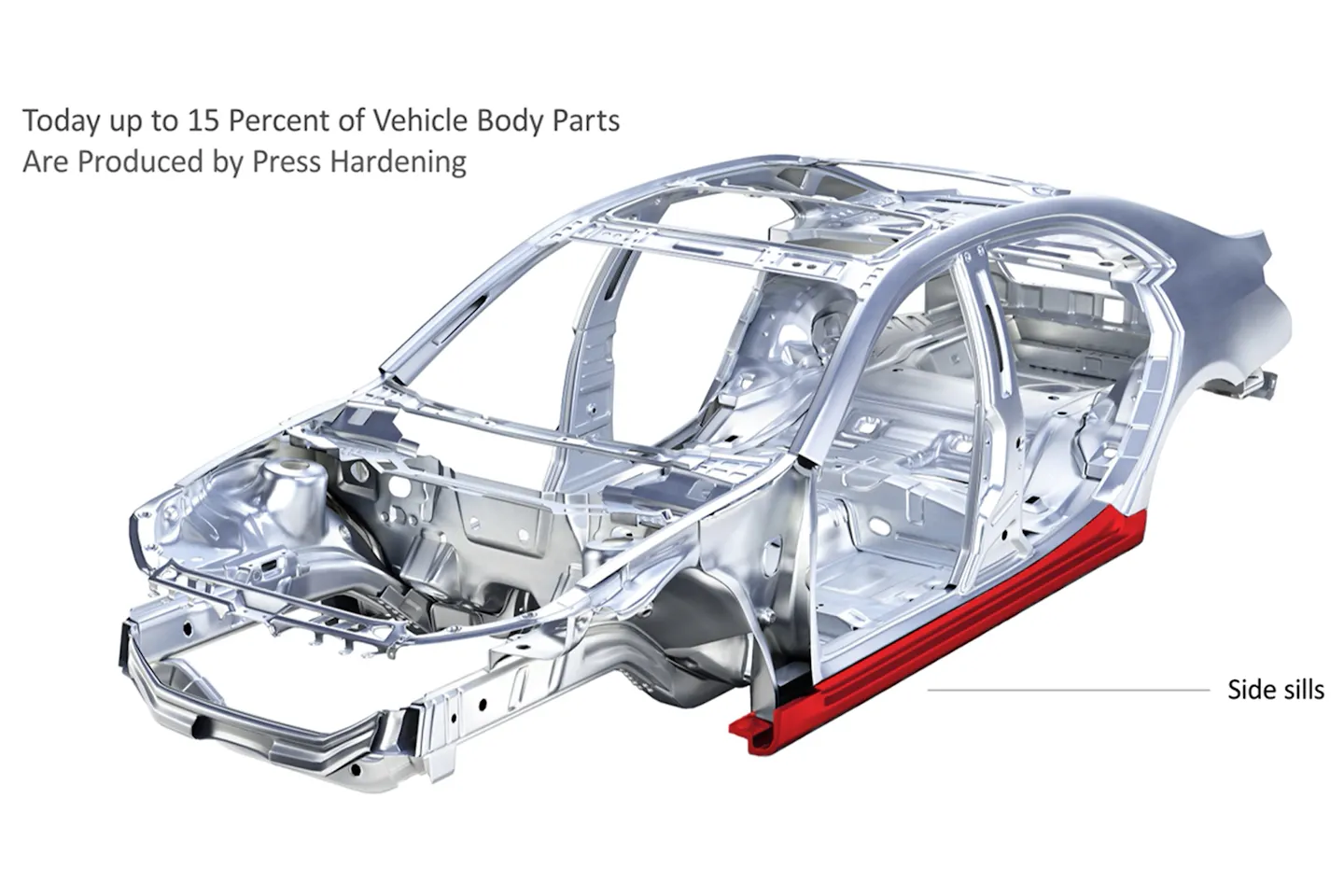

Why Monitor the Process of Press Hardening?

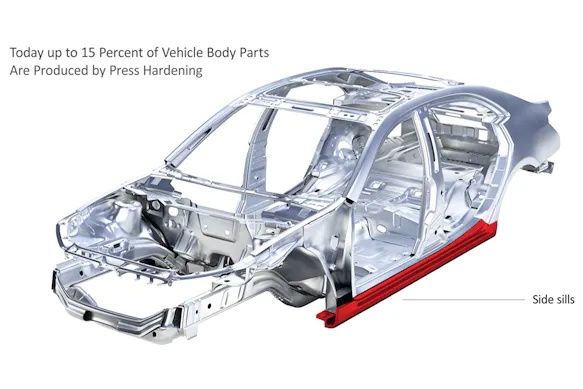

Automotive low weight components demand a precise microstructure and corresponding local strength distribution. Good reasons to monitor the process of press hardening by the use of infrared cameras.

Thermography in Use in Press Hardening

The automated test system PRESS-CHECK from InfraTec serves to control the production process during press hardening. It is equipped with several infrared cameras, which monitor the furnace exit, the moment before and after pressing as well as the cooling of the pressed parts. Thus, a complete temperature measurement and position monitoring is easily possible - high-level quality control due to thermography.

Frequently Asked Questions

Hot forming is a process in which metal workpieces are heated and formed above the recrystallisation limit with little force. In the process, repetitive recovery and softening processes take place. Hot forming processes include forging, hot rolling or extrusion. Hot forming is also referred to as form hardening or press hardening.

The main difference is the temperature at which the forming process takes place. While it is above the recrystallisation point in hot forming, it is below it in cold forming. In addition, less force is needed for hot forming.

Press hardening (also form hardening) is a process for the hot forming of sheet metal. In this process, the workpieces are heated and then formed by a water-cooled tool and cooled at the same time. This is how robust components are created.

During hot forming and press hardening, a consistently high production quality is ensured by thermography and area-based monitoring of the process temperatures, which offers significant advantages over exclusively punctual temperature measurements at reference points.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Features and Benefits

Infrared cameras optimised for temperature control at the furnace exit, before and after hot press stamping or hot forming

Monitoring of the entire surface of the sheet instead of point measurements

Presence detection, position recognition, double sheet detection

Fully automatic, process-synchronous operation

No additional setup time

Increases process efficiency and safety by automatically sorting sheets or stopping the press to prevent damage

Temperature measurement and classification of sheet metal parts

Adaptation to different press manufacturers through flexible system structure and data interface

Control of multi-zone components (tailored tempering) for partial press hardening in one process step

System Structure

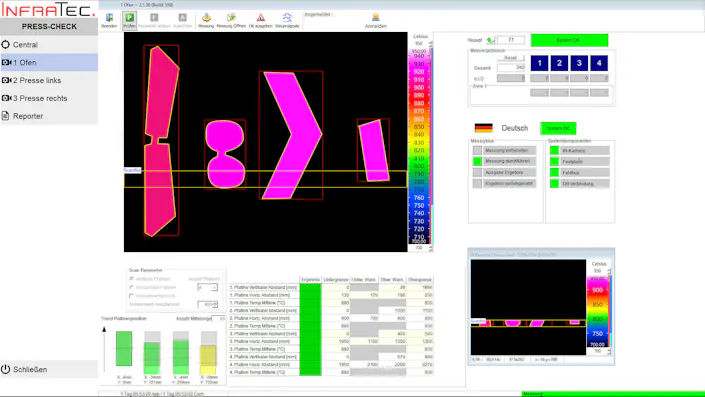

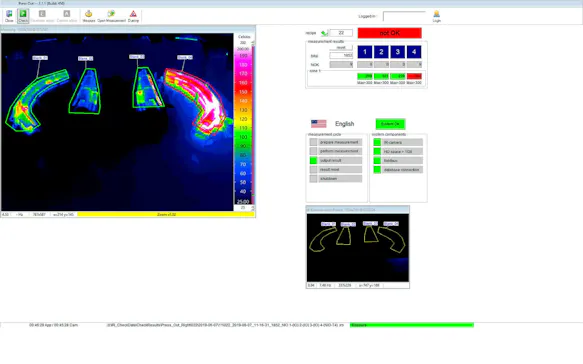

PRESS-CHECK Software

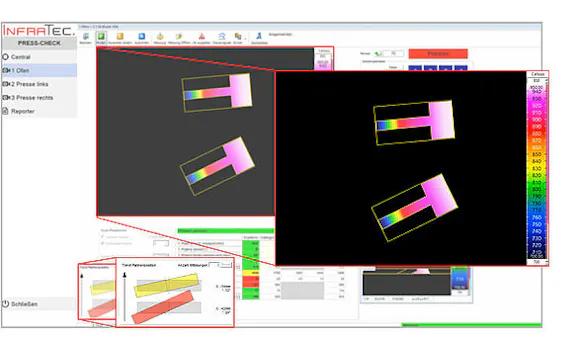

Parameter setting, monitoring, operation, representation, evaluation and reporting by the software

Automatic test mode for temperature, loading and position control

Ease of use via intuitive user interface

Easy parameterisation and setup

User management

Data and recipe management

Automatic data transfer to supervisory control system

Easy integration into QM systems

Scene-based, geometric and thermal characterisation of the heat-treated sheet metal blanks at the furnace exit after hot forming or hot press stamping

Automatic inline detection of components, even if they are only partially visible

Automatic adaptation to variable process speeds

Dynamic measuring field (ROI) - creation "on the fly" to determine the position and thermal data according to the component recipes

Statistical data analysis of position information for automatic adjustment of the sheets’ furnace loading position

Transition zones of multi-zone components are detected, geometrically and thermally measured

Defect Patterns of a Moulded Part

Automated Monitoring in Running Operation

Position and temperature control during the press hardening process

Creation of complete images from several individual images, even with limited on-site conditions on site

Automated evaluation of heat transfer zones on horizontal or moving components

Fieldbus interface to machine control

Product Flyer

Get all the information you need at a glance in our product flyers