Early Fire Detection in Incineration Plant

The Amager Resource Center (ARC) is a waste incinerator like no other. From the roof of the Waste to Energy facility, skiers and snowboarders wind their way down on green plastic mats from a height of about 80 meters, even in the summer. The city hall of the Danish capital, Copenhagen, is just five kilometres away. The location, which is almost in the heart of a European capital, as well as its use as a public leisure centre, shows how much confidence operators place in the safety of the ARC. An important component in the security concept is the WASTE-SCAN infrared monitoring system for early fire detection by InfraTec.

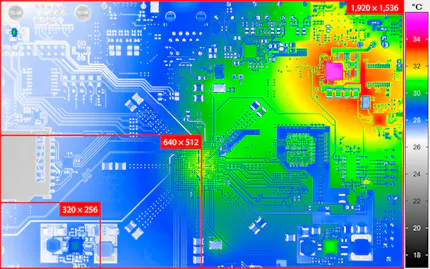

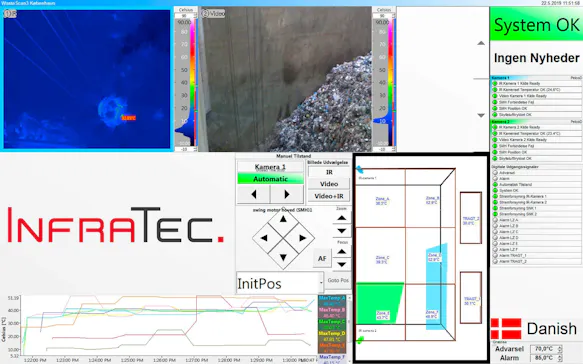

At the heart of this solution are two high-performance camera heads, each consisting of an infrared and visual camera as twin systems. They are equipped with pan-tilt heads and are used to monitor the waste bunker and feed hopper. The twin cameras, infrared and visual, allow images of both channels to be superimposed. This ensures excellent orientation within the bunker and supports the reliable assessment of hazardous and process conditions.

InfraTec Solution

Amager Ressource Center (ARC)

Waste Incineration Plant

www.a-r-c.dk

Thermography automation system:

WASTE-SCAN infrared monitoring system

Direct Connection to Complete Extinguishing System

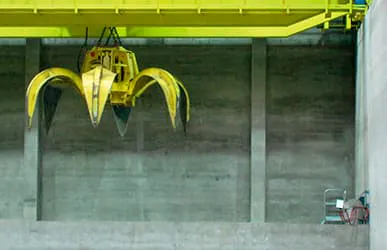

Integrated into special protective housings, the cameras are installed on powerful pan-tilt systems. Based on their electronic control, areas can be monitored with maximum resolution and hotspots can be detected as quickly as possible. The infrared cameras are directly connected to the extinguishing system of the ARC. As soon as they detect a fire, an alarm is automatically triggered. As a result, the cameras transmit the information to the extinguishing system concerning which zones are affected. Based on this information, two of the three water cannon systems then extinguish exactly these affected areas of the bunker. If the notification relates to one of the feed hoppers, the sprinkler system there activates.

Thanks to such features, WASTE-SCAN meets the latest fire protection requirements. At the same time, it impresses with its user-friendly handling. Crane operators of the waste-to-energy system can control the system directly from the crane via a touch display. In the control room, the operators of the ARC see all relevant information on a standard monitor. The corresponding control cabinet with integrated industrial PC can also be found there. The system status is visible at a glance from the control room as well as from the crane. At the same time, central parameters such as the temperature limit values are displayed there, which serve as the basis for triggering the alarm. All the components of WASTE-SCAN, such as cameras, pan-tilt heads and connection cables, are designed for safe, continuous operation in harsh environments.

Energy Generation and Recycling of Building Material

The ARC Waste to Energy Plant is a combined heat and power unit owned by the five Danish metropolitan municipalities of Copenhagen, Dragør, Frederiksberg, Hvidovre and Tårnby. About 435,000 tons of waste are converted into electricity and district heating per year from the catchment area. A total of around 100,000 households benefit from it. The heat generation of the ARC is additionally optimised by systems for flue gas condensation and heat pumps. In addition to the energy products, a slag results from about 15 to 20 percent of the delivered waste, which is re-used as material in road construction.