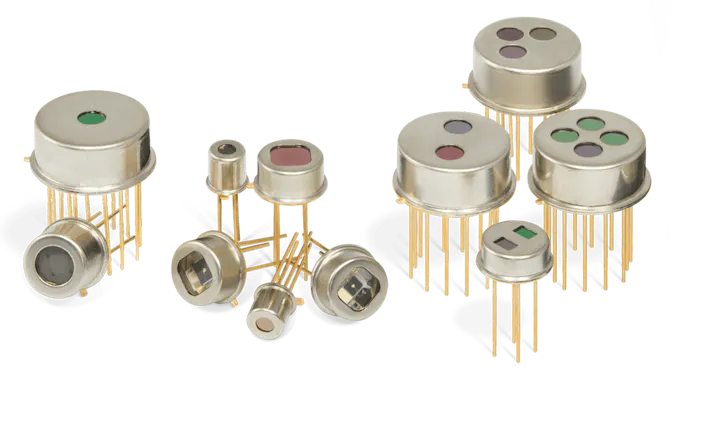

PYROMID® Multi Channel Detectors

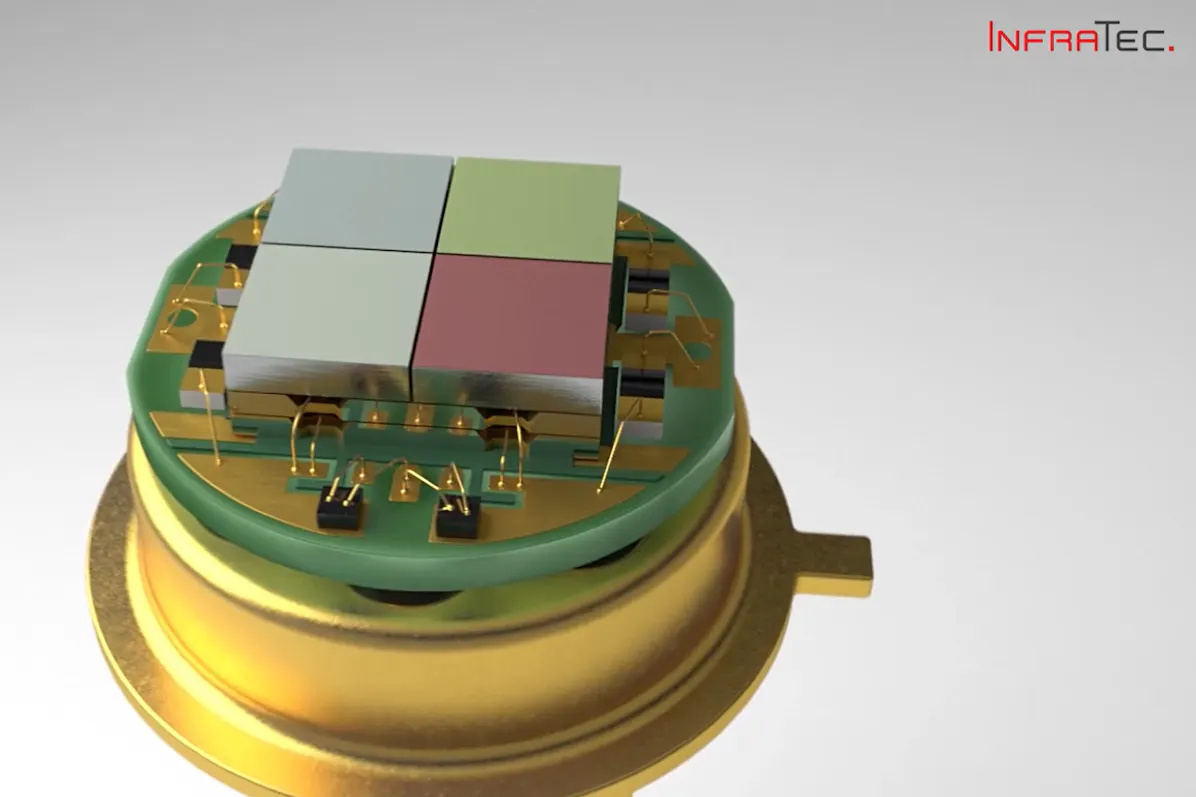

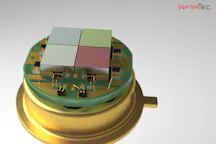

The PYROMID® brand stands for infrared detectors with compact stack design, the LRM detector family, as well as multi channel detectors with internal beam splitters, in particular for gas analysis and flame detection.

Features of PYROMID® multi channel detectors from InfraTec

Multi channel detectors with up to eight channels

Integrated beam splitter or micromechanical frame

Easy integration into measurement devices

For use in gas analysis and flame detection

Type | close Number of measuring channelsNumber of Channels | close TO18, TO46: 5.4 mm in diameter Housing | close Size of the circular or rectangular aperture through which radiation hits the sensitive elements.Aperture (mm) | close Voltage Mode: The pyroelectric current is initially converted into a voltage by an RC network followed by a conversion to lower impedance. Current Mode: The pyroelectric current is permanently compensated by an OpAmp. The current required for this generates a voltage drop across an RC network in the feedback path which serves as the measurement signal. Operating Mode | close Integrated signal condition like integrated junction field effect transistors (JFET) for detectors in voltage mode or integrated operational amplifiers (OpAmp) for detectors in current mode. Amplifier | close A pyroelectric detector is sensitive to changes in temperature. Changes in ambient temperature have an influence on the measurement signal and shifts the operating point. This effect reduces a thermal compensation. Therefore, each pyroelectric element gets an additional optically inactive element, which compensates for unwanted currents. Thermal Compensation | close Patented micromechanical chip attachment (LowMicro) by InfraTec to reduce the effects of interfering impact sounds. Low Micro | close As a key parameter, the specific detectivity D* characterizes the signal-to-noise ratio of infrared detectors. Specific Detectivity* | |

|---|---|---|---|---|---|---|---|---|---|

LRM-274 close Single supply operation | 4 | TO8 | 8.5 × 8.5 | Current Mode | OpAmp | 4.0 | |||

LRM-278 close single supply operation | 8 | TO8 | 8.5 x 8.5 | Current Mode | OpAmp | 4.5 | |||

LIM-032 close Integrated Beam Splitter | 2 | TO39 | 2.8 x 2.8 | Voltage Mode | JFET | 2.9 | |||

LIM-011 close Integrated Beam Splitter | 4 | TO8 | 2.8 x 2.8 | Voltage Mode | JFET | 0.8 | |||

LIM-054 close Integrated Beam Splitter | 4 | TO8 | 2.8 x 2.8 | Current Mode | OpAmp | 0.42 | |||

| 2 | TO18 / TO46 | 3.0 x 2.0 | Voltage Mode | JFET | 4.0 | ||||

| 2 | TO18 / TO46 | 3.0 x 2.0 | Voltage Mode | JFET | 2.0 | ||||

| 4 | TO39 | 5.0 x 5.0 | Voltage Mode | JFET | 4.7 | ||||

LRM-284 close Single supply operation | 4 | TO39 | 5.0 x 5.0 | Current Mode | OpAmp | 4.5 | |||

LRM-244 close single supply operation | 4 | TO8 | 8.5 x 8.5 | Current Mode | OpAmp | 6.0 | |||

| 2 | TO18 / TO46 | 3.0 x 2.0 | Current Mode | OpAmp | 3.0 | ||||

LIM-082 close Integrated Beam Splitter | 2 | TO39 | 2.8 x 2.8 | Current Mode | OpAmp | 1.9 |

* in 10

** in 10

*** bei R

**** in 10

LRM Detectors

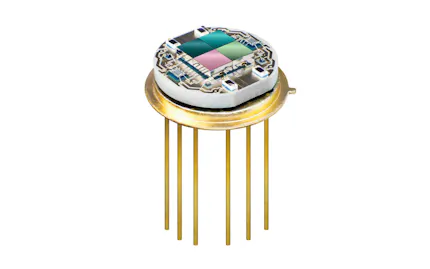

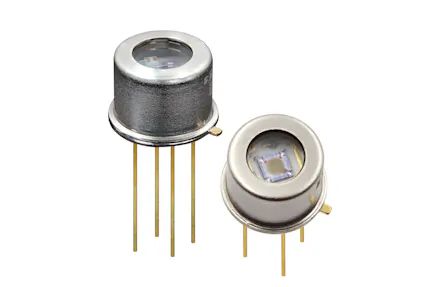

Miniaturised Multi Channel Detectors with Compact Stack Design

Cutting Edge Technology in Most Confined Spaces

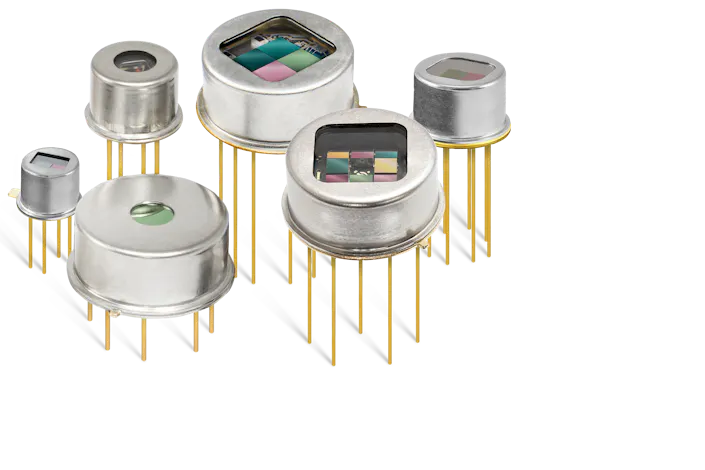

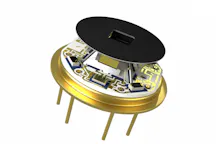

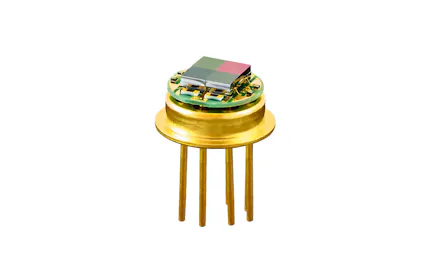

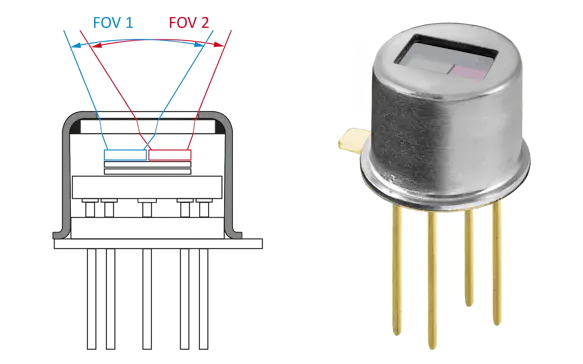

LRM detectors by InfraTec, a series of miniaturised multi channel detectors, offer an extremely wide field of view (FOV) in combination with a compact design and attractive pricing. Their most obvious hallmark is a robust central window in the cap, e.g. made of silicon. It offers reliable protection against environmental influences such as penetrating moisture. Optionally soldered to the housing this central window enables complete hermetic sealing.

Innovative Modular Stack Design

The channel filters are placed inside the detectors. Shielded from mechanical stress as well as from other strains from harsh environments they are located close to the pyroelectric elements. The reduced distance and the central window integrated into the detector caps are two of the factors that ensure a wide FOV. At the same time, all elements are placed close together inside the detectors. This allows more radiation to reach the pyroelectric element and therefore a higher signal. In addition, since the optical crosstalk of the individual channels is suppressed very effectively, the entire detector series proves to be extremely powerful. The compact, miniaturised construction allows for more analysis channels with unchanged package size. Or, the same number of channels can be integrated into significantly smaller packages.

High-tech in the Smallest Space

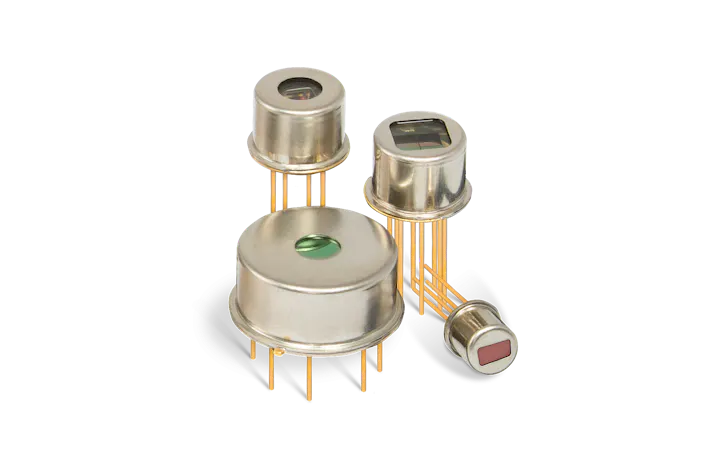

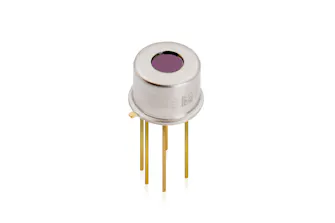

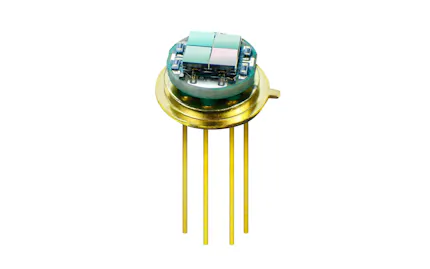

The LRM-292 pyroelectric detector from InfraTec is, next to the LRM-202, the world‘s smallest multi-channel detector with integrated operational amplifier and thermal compensation. With a diameter of only 4.7 mm, the LRM-292 is predestined for measuring low gas concentrations at small measurement volumes. Fast gas changes, low gas concentrations, and short gas exchange times are not a challenge for the pyroelectric detector in a compact TO46 housing.

The LRM-292 and LRM-202 owe their compact design to the tried-and-tested stacked construction method. Its unique design means that both detectors have a field of view (FOV) of 60°, exposing a very large proportion of the radiation to the pyroelectric elements. This generates high amplitudes of the output signal, which supports external signal amplification.

LRM-292 - Small Multi Channel Detector with Current Operation

In the LRM-292, two integrated operational amplifiers are connected as transimpedance amplifiers. The current mode produces higher output signals than the LRM-202 in voltage mode. This simplifies signal processing and provides an excellent signal-to-noise ratio even at frequencies above 10 Hz. Additionally, the LRM-292 has been designed to use only one supply voltage, thereby reducing the amount of circuitry required.

LRM Detectors at a Glance

Assortment of two, four and eight channel detectors

Operation in voltage mode or current mode

Extremely wide FOV provides powerful performance

TO46, TO39 and TO8 housings available

Robust central window for protection against penetrating moisture

Option for complete hermetic sealing

Available with thermal compensation

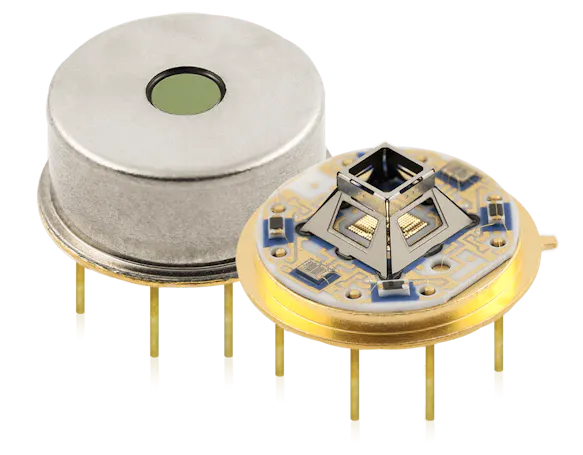

Compact Pyroelectric Detectors Based on Micro-machined Chip Carriers

A miniaturized multi channel detector differs in many ways from a more conventional multi-channel detector. For example, it features special chip carriers. The influence of such elements on the performance of these special detectors is clearly illustrated in this technical article.

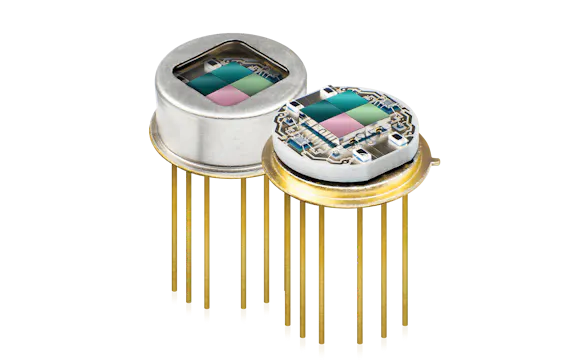

Beam Splitter Detectors

Precise and Stable Measurements for Long-term Applications

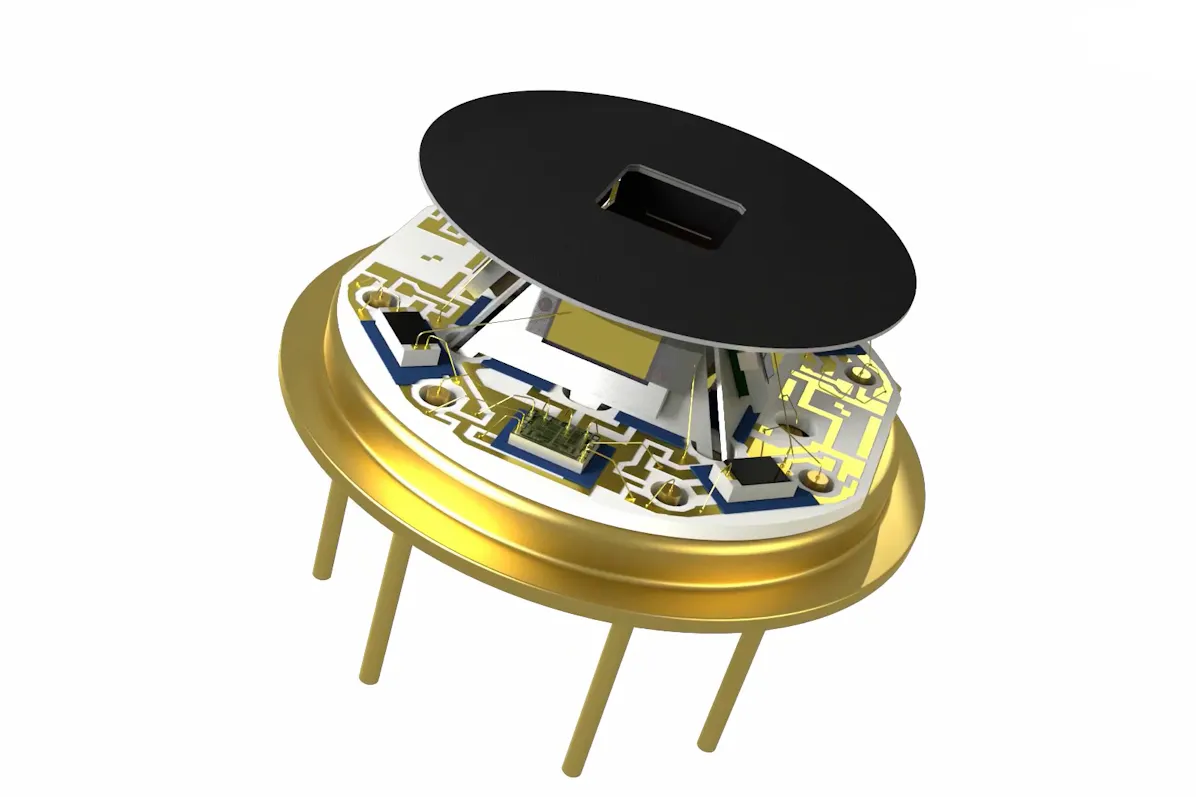

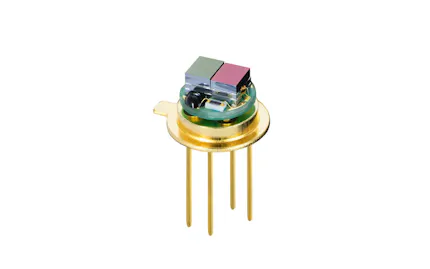

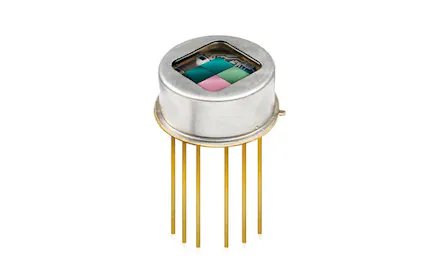

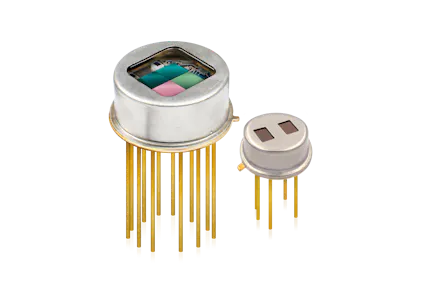

Unconventional Solution for Precise Measurements

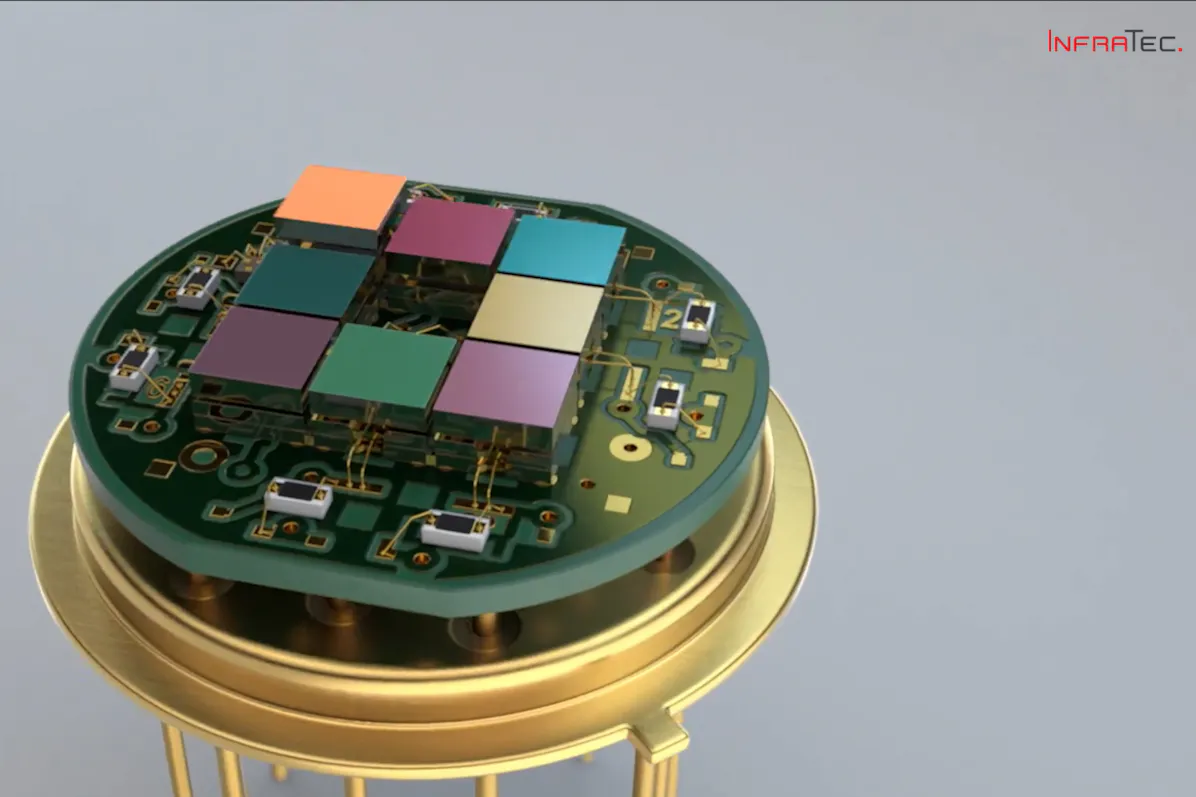

Beam splitter detectors are perfectly suited for measurement tasks that demand accurate and stable measurement results over the long term. These multi channel detectors are equipped with only a single aperture. They contain an array of micro mirror surfaces working as an internal beam splitter. Due to the detector’s single aperture opening, major parts of the incoming radiation impinges reflectively to the pyroelectric crystal. This allows for very precise NDIR gas analysis particularly in gas detection technology. To solve such measurement tasks, a gas cell with an effective diameter of just 2.5 mm is sufficient. Apart from an accelerated exchange of gas, this results in very low dead volumes of the measuring system. Measurement devices equipped with the detector can be correspondingly smaller. The permanently stable signal ratio between the individual channels ensures a high degree of measurement accuracy.

One of a Kind – Reflection Beam Splitter

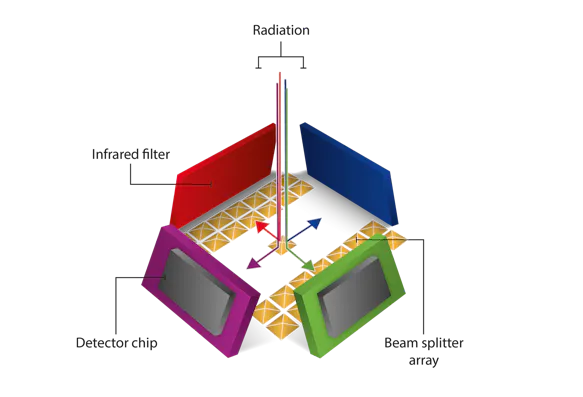

The beam splitters used by InfraTec are solely reflection beam splitters and consist of highly reflective gold plated microstructures. The division of the beam into two or four spectral channels is done only within the detector.

The radiation entering through the aperture opening of the detector is split into several radiation beams of equal intensity but in different, predefined directions within the detector based on the architecture of the innovative microstructure inside. Each of the beams impinges on a corresponding pyroelectric sensor element with an upstream optical filter.

Mechanical expansions in the optical system of the measurement device, ageing effects or any possible contamination of these detectors are already accounted for before the beam is split and thus affect all channels equally. This minimises differences between the measurement channels and the required beam diameter. The microstructures vary according to the detector type. In quad channel detectors these resemble four-sided micro-pyramids, whereas in dual channel detectors these are V-shaped grooves.

Advantages of Beam Splitter Detectors

Multi channel detectors with a single aperture

High degree of measurement accuracy due to a permanently stable signal ratio between the individual channels

Simple constructive solutions allow exact same reflected intensities of the individual radiation beams

Very low dead volumes of the measurement systems

Small gas cells enable easy integration into measurement devices

PYROMID® Brochure

Get further information about miniaturised detectors for gas analysis and flame detection.

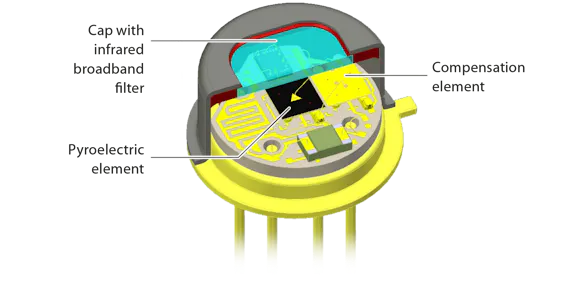

How Does a Pyroelectric Detector Work?

Pyroelectric crystals have a rare asymmetry due to their single polar axis. This causes their polarisation to change with temperature. This so-called pyroelectric effect is used in sensor technology. For this, a thin pyroelectric crystal is coated perpendicular to the polar axis with electrodes. On the upper electrode of the crystal, an absorbing layer (black layer) is applied. When this layer interacts with infrared radiation, the pyroelectric layer heats up and surface charge arises. If the radiation is switched off, a charge of the opposite polarity originates. However, the charge is very low. Before the finite internal resistance of the crystal can equalise the charges, extremely low-noise and low leakage current field-effect transistors (JFET) or operational amplifier (OpAmp) convert the charges into a signal voltage.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our experienced engineers, receive further technical information or learn more about our additional services.

Detector Search

InfraTec offers different product groups including approximately 50 standard pyroelectric detectors. Detectors with reduced microphone technology and integrated operational amplifier as well as digital detectors are part of our product range.

Choose your suitable infrared detectors with the help of our detailed detector search.