- 2021-08-13Life with PyroelectricityFerroelectricity: 100 years and very much alive and kicking. This phenomenon has been researched and used until the present day.Read onDownload ZIP-File (3068 kB)

Science lives from ambitious and inquisitive people. Progress would be inconceivable without them. In the field of infrared technologies, the researchers and developers of InfraTec make a decisive contribution to the advanced development of pyroelectric detectors with their visionary ideas and expertise.

- 2021-07-16A Successful Cooperation against Plant DiseasesData Fusion in Plant Phenotyping for Cercospora Detection in SugarbeetsRead onDownload ZIP-File (944 kB)

Various sensor technologies had been evaluated regarding their usability for the detection of the plant disease Cercospora in the joint project „Data Fusion in Plant Phenotyping for Cercospora Detection in Sugarbeets“ (DataPlant), funded by the German Ministry of Food and Agriculture.

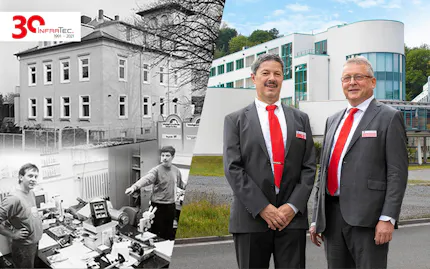

- 2021-06-2430 Years Under the Spell of InfraredHow an efficient, medium-sized Dresden high-tech company developed from one idea.Read onDownload ZIP-File (3448 kB)

Infrared technology has exclusive and sometimes mysterious properties because it uses electromagnetic radiation, an invisible, but at the same time, omnipresent force. It can be used, for example, to measure temperatures and gas concentrations, for early fire detection and to track down energy losses.

- 2021-06-02Always Up to Date – New Edition of InfraTec's Detector CatalogueThe specialist reading for sensor industry including the world's first eight-channel detector and other new members of the LRM family.Read onDownload ZIP-File (4336 kB)

Pyroelectric detectors "Made in Germany" in great variety. An in-house research and development department. This and much more is offered by the owner-managed company InfraTec GmbH Infrarotsensorik und Messtechnik from Dresden with locations in the USA, Great Britain and China.

- 2021-05-06Infrared Cameras as Life Insurance for a Billion Dollar ProjectAn InfraTec thermography automation solution supports the monitoring of one of the world's largest solar tower power plants in the middle of the Atacama Desert.Read onDownload ZIP-File (4236 kB)

Solar power plants usually suffer from the disadvantage that they only supply energy when the sun is shining during the day. CSP (Concentrated Solar Power) solar tower power plants are different: they charge a large thermal buffer storage during the day, which allows the continuous generation of electrical energy also at night‐time. One of these solar tower power plants recently went into operation in the middle of the Atacama coastal desert in Chile.