Online Event: Thermography and Digital Image Correlation

In the field of materials testing, numerous methods have been established including infrared thermography. Often, it is the combination of different methods that enables the desired results for component characterisation. For example, you can analyse displacements and mechanical deformations of material samples and components parallel with its thermal reaction.

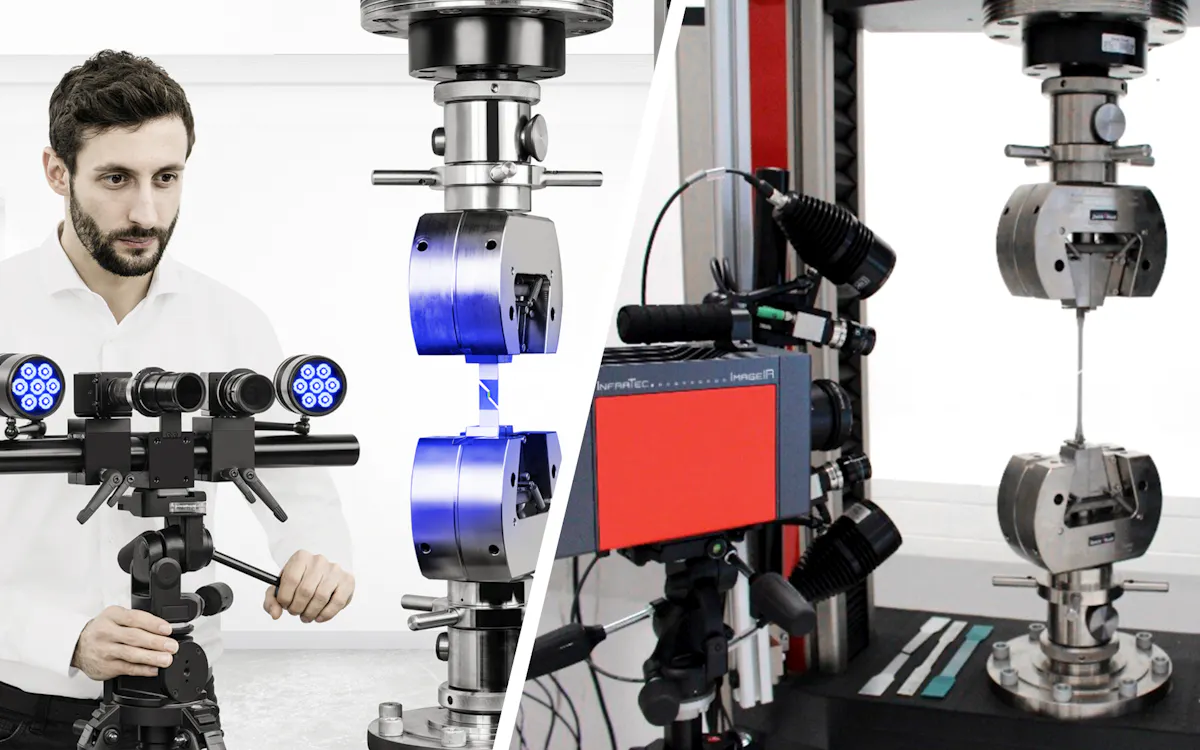

The ARAMIS system by ZEISS/GOM, using digital image correlation (DIC), offers the appropriate measurement instrument for such investigations. Corresponding DIC evaluations can be combined with thermographic measurements using infrared cameras from InfraTec. The combination of measuring results from the DIC and temperature measuring data from infrared cameras offers the simultaneous analysis of the thermal and mechanical behaviour of test specimens in the materials and components testing field. Materials like e. g. metal, plastics and composites as well as electronic power components can be deeply analysed in this way.

With the special software feature in ARAMIS, you can analyse the correlation between mechanical deformations and thermal behavior in detail and reduce your development time thanks to the comprehensive understanding obtained about your materials or components. If you would like to know how this works and which benefits it offers you, we invite you to join our online event.

Online Event: “Thermography and Digital Image Correlation – A Winning Team in Electronics and Other Applications.”

Including the technical lectures from thermography practice:

"Heat & Measure – ARAMIS 3D-Deformation and Thermography for Testing Applications"

Speaker: Burak Acun, ZEISS Industrial Quality Solutions / Carl Zeiss GOM Metrology GmbH

Date: Tuesday, 11 February 2025

Time: 10:00 AM – 12:00 PM (CEST)

Registration