3D Printing under the Thermographic Microscope

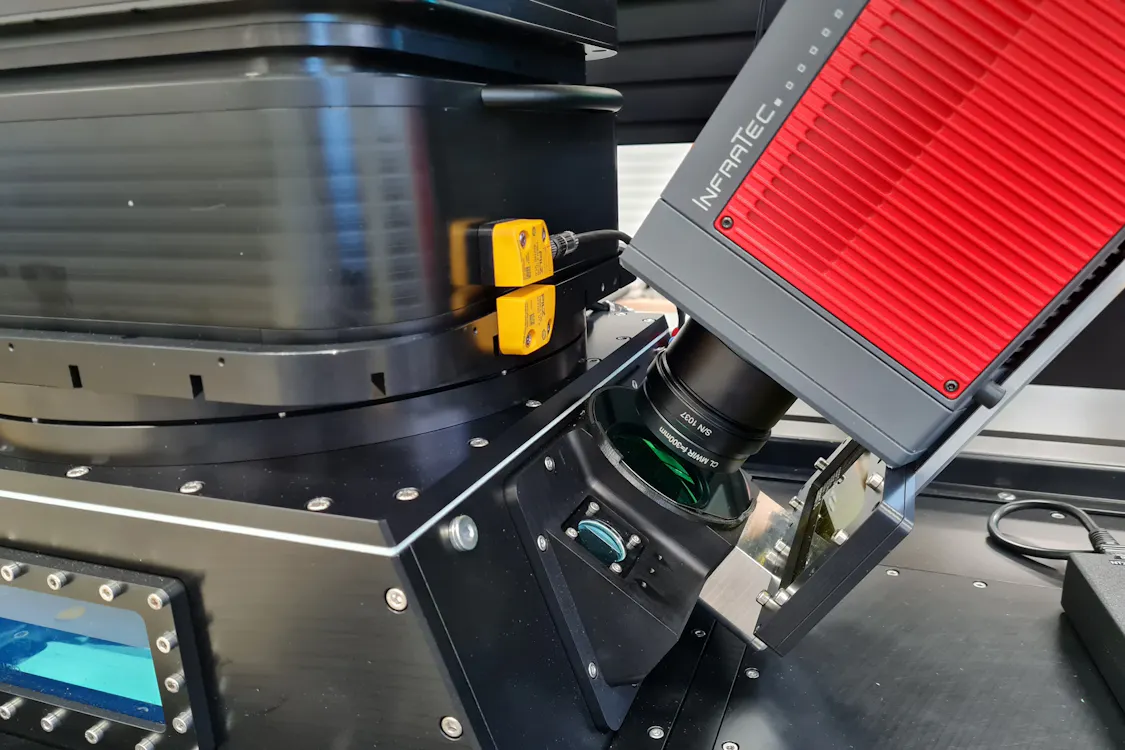

Additive manufacturing has developed rapidly from its original field of prototype manufacturing, becoming a complete production technology for use on an industrial scale. Precise monitoring of machinery, equipment, materials and – above all – temperatures is of vital importance in this regard. Once the measured temperature data of components, materials or melting processes has been recorded and analysed using thermal imaging, this establishes a basis for a comprehensive understanding of the process. If a precise knowledge of the temperature development and distribution over time is obtained, and this is used to derive the targeted thermal control of the production process, the reproducibility of the process is increased and new parts with improved properties can be developed. Aconity3D supports the industrialisation of the additive manufacturing process also by using infrared cameras from InfraTec.